Looking for a precision CNC machining partner? while before that you might as well to learn it well. CNC index-controlled machine tools are programmed and controlled by CNC machining languages, which are mostly G codes. The CNC machining G code language tells the Cartesian position coordinates of the machining tool of the CNC machine tool and controls the feed speed and spindle speed of the tool, as well as the tool changer, coolant and other functions. How many types of CNC machine tools are there? The following content will introduce various CNC machine tools, you can find the difference between them.

Different Types of CNC Machine Tools

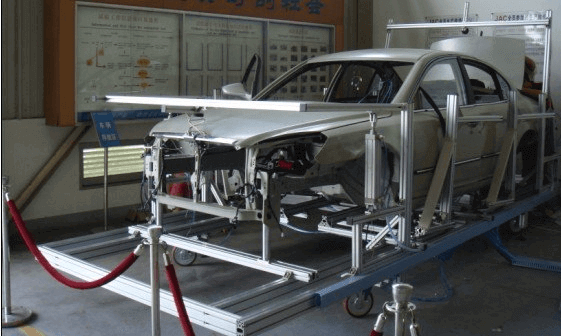

CNC (computer numerical control) machine tool is an automated machine tool equipped with a program control system, which can achieve the purpose of processing and producing complex, precise, small-batch, and multiple CNC machined parts. In precision CNC machining are many types of CNC machine tools used in the CNC machining process, which can be divided into the following categories according to different processing methods.

Different Types Depend on Functions

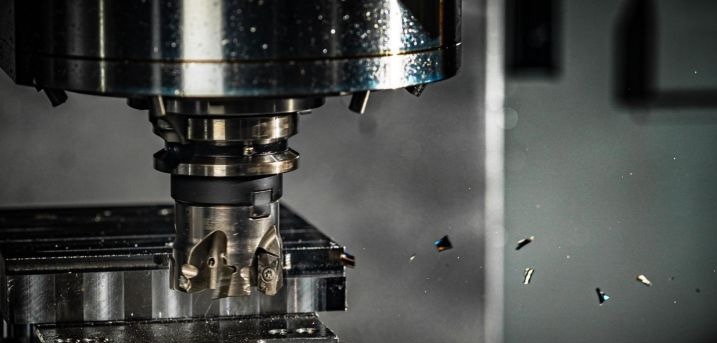

CNC milling machines: used to create shapes, slots, holes, notches, grooves, pockets, and specialty faces, and perform the machining process of manufacturing CNC milling parts, the rotary cutting tools on the mill to remove material from the stationary workpiece.

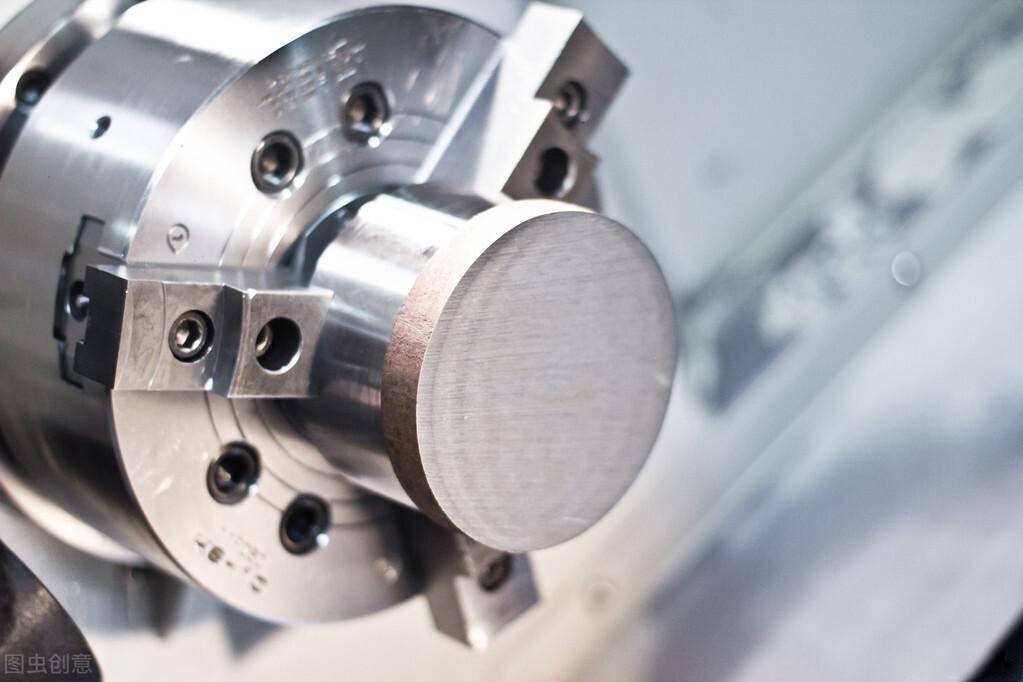

CNC lathes: It refers to a machine tool whose main movement is the rotation of the workpiece, and the movement of the turning tool is the feed movement to process the rotating surface. It can be used to process various rotary forming surfaces. There are many types of lathes, which can be divided into the following categories according to different processing methods.

CNC drilling machines: Used for hole processing of workpieces, such as center drill positioning, drilling, reaming, countersinking, reaming and boring, and other hole processing operations. Continuous control function through the linear interpolation, circular interpolation, or complex curve interpolation movement of the CNC milling machine, milling the plane and curved surface of the workpiece.

CNC plasma cutters: Used for hole processing of parts, such as drilling, center drilling positioning, countersinking, reaming, reaming and boring processing operations. The continuous control function uses the circular interpolation, linear interpolation or cyclic curve interpolation of the CNC drilling and milling machine to mill the curved surfaces of the parts.

CNC grinders: A machine tool that grinds the surface of a workpiece.

Point-to-point Systems and Contour Systems.

Point-to-point system: The material and the tool are placed in certain fixed relative positions until the tool is processed and returned. This type of equipment includes drilling machines, boring machines, and tapping machines.

Contour system: The machine tool cuts the material according to the contour of the part, so it works on a continuous path. Such equipment includes lathes, milling machines and milling machines.

Five Groups According to the Axis

2-axis CNC machine tool: A machine tool can only use two axes, such as a lathe, and the tool moves in two directions, such as X and Z.

2.5-axis CNC machine tool: It is also a 3-axis system, but the movement is not three-dimensional. The X and Y axes move to the position first, and then the third axis starts to work, such as drilling and tapping machines.

3-axis CNC machine tool: Three-axis (X, Y, Z) three-axis motion at the same time. It is currently the most widely used, most versatile, high-precision and high-precision machine tool. It can be used for automatic/interactive operation, slot milling, and drilling. And cut sharp edges.

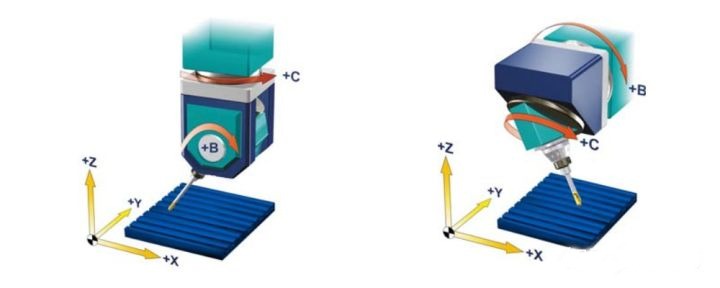

4-axis CNC machine tool: A 3-axis machine tool that rotates one more circle on the A-axis or B-axis. Common examples are vertical machine tools or horizontal machine tools. In 4-axis machining, milling is performed on the additional axis, while the operations on X, Y, and Z are the same as the 3-axis system, and the rotation on the A or B axis is the axis around the X-axis.

5-axis CNC machine tool: A 3-axis machine tool with additional rotation in two directions (Y and Z) on the A-axis and B-axis. The rotation is given by the movement of the bed and the spindle (pivot point) respectively. The 5-axis machine is an advanced CNC machine. Its multi-dimensional rotation and tool motion allows the creation of precise and complex parts because it improves access to undercuts and deep pockets, unparalleled finish, and speed, and is often used for advanced applications such as Aerospace parts, artificial bones, titanium parts, oil and gas machinery parts, military products, etc.

Open-loop Systems and Closed-loop Systems

From the control loops side, CNC machine tools can be divided into open-loop systems and closed-loop systems.

An open-loop CNC machine tool is a system in which the communication between the controller system and the motor is away. It is a very simple process in the open-loop system. According to the user’s purpose, the CNC software uses the necessary step and direction signals to create information. The computer transmits this information to the controller. Then the controller supplies power to the motor without feedback. Open-loop CNC machine tools use stepper motors.

The closed-loop CNC machine tool owns a feedback system to monitor the output of the motor and can also correct errors in position, speed, and acceleration. The feedback can be fed back to the CNC controller or computer. The former is more common. The system that feeds back to the signal generator or computer usually exists in high-end machines.