What is the difference between CNC vise and ordinary vise?

If you are very familiar with and understand the work in a hardware store, you will find that the vise in the mechanical workshop may be very different from what you think.

Differences Of Shapes

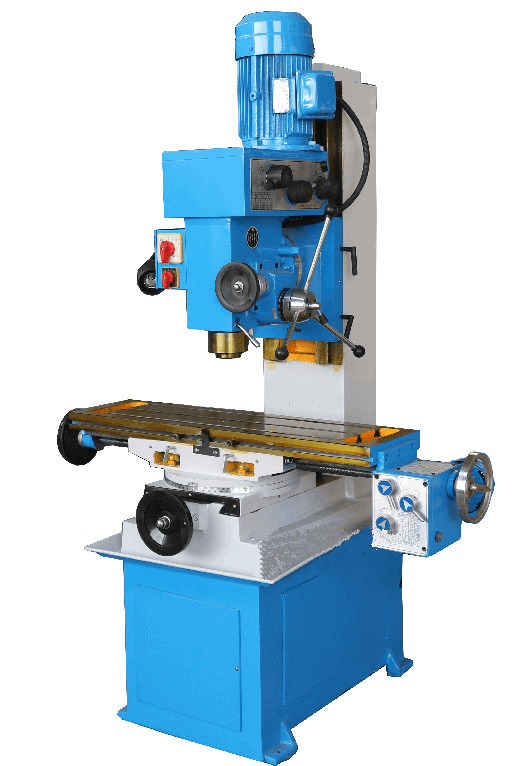

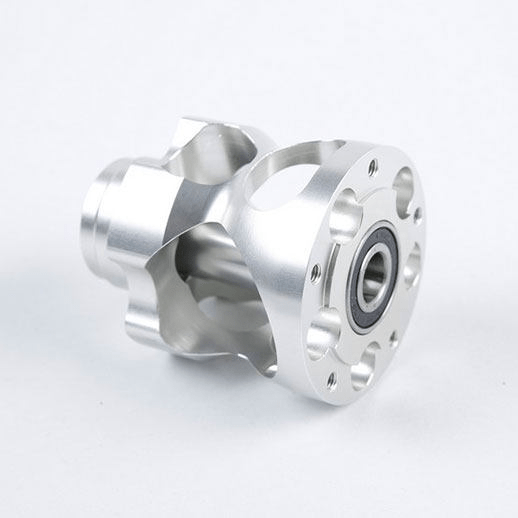

Contours and shapes: We prefer tools commonly called CNC vices. These are vises with flat and polished surfaces. This allows you to do two key things: you can turn the vise up from the side, or you can use these precision flat edges to move the vise easily, whether you are cleaning with an indicator or have a fixed plate with several positioning pins, You can push the vise onto those towel pins.

Differences Of Jaws

The CNC vise is different from the old machinist vise. The latter has a cast flange like a lip around the outline of the vise. They are no problem. The CNC vise has the advantage in terms of convenience. The two are also different in how to close the movable jaws.

Ordinary vise: When you rotate the screw, you move the movable jaw toward the part and begin to clamp it. The jaw will move on the path of least resistance. Because it is a movable jaw, there must be a certain gap before it can move or slide. When you tighten it, it is easy to the palate. The chin will want to deflect or bend instead of directly entering your part.

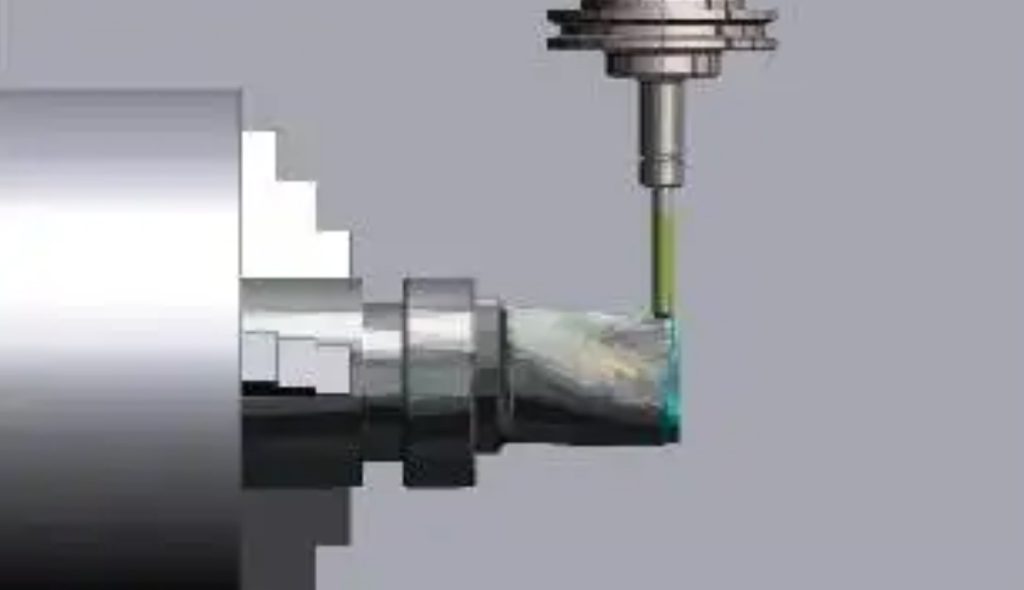

CNC vise: This problem is overcome by two opposing inclined planes. When you tighten that screw, the top triangle will push the lower triangle on the movable jaw. In this way, not only can the clamping force be provided forward, but also the clamping force can be provided downward to help minimize or eliminate jaw elevation.

The jaw itself: On a normal vise, you will see serrations. On a machine vise, its saw teeth are very smooth, and when you are working on a home improvement project, they will bite in pairs. It doesn’t work in the work of a machinist, because we want to hold our parts accurately, and don’t want to damage them with the marks of serrations. Even though the machinist’s vises have smooth jaws, they can still provide incredible work-holding force through the clamping force exerted by the screws. A 6-inch mechanical vise can usually provide five to ten thousand pounds of clamping force on the part.

Differences Of Clamping Force and Pressure

Clamping force: Clamping force means that when you apply a consistent torque on the screw, it will push forward with a consistent force.

Clamping pressure: The clamping pressure is related to how you distribute the force on the surface area of the part. You can clamp relatively thin materials in the jaws of the vise without affecting the workpiece clamping. Because you are using a fixed amount of force to distribute it over a smaller surface area. This will bring you relatively consistent pressure.

Take the part 203 as an example. Starting with a bracket part, we use a traditional vise, but the jaws are slightly different. To minimize the amount of material, we use a talon paw. This material should be extruded, and mainly of it is aluminum. The extrusion line along the x-axis of this part. This material will have a certain amount of tension or stress. Although aluminum 6061 does not have as much stress as cold-rolled steel, it still has some stress. When using the traditional vise jaws, the parts may bend or bend a little. The way to solve this problem is by sending the material to decompressing, it can be done in the form of a blank, or it can be done after you finish operation -1 and you are left with Additional materials. You can also minimize this by trying to remove equal amounts of material on both sides of the part. You can also try to cut off the bottom plane, leaving as much material as possible to accommodate this bending, and re-clamp it under no pressure to re-pave the material again. In processing, JTR CNC machining provider always doing the best to support the best service and providing you most professional advice such as above for you.