Die Casting

JTR offers industrial die casting services for Aluminum, Zinc, Magnesium, etc. Consistent die casting, predictable cycle times, and considerable cost savings over other methods of manufacturing are possible when you work with JTR. Dedicated to providing exceptional service with superior die casting, tooling, along with metal finishing and machining, JTR specializes in superior aluminum, magnesium, and zinc alloy die casting.

Our engineers and production staff make sure that they employ advanced die casting machines and processes that produce your parts economically and with reliable quality.

Our Die Casting Capabilities

Advanced die casting machine & equipment

Up to 300 Tonne hot chamber capacity

Up to 900 Tonne cold chamber capacity

A wide range of Al, Zn, and Mg alloys

Integration of product die casting and installation

High-quality product surface

Die Casting Materials

|

Alloy Group |

Description |

Specific Alloys |

|

Aluminum Alloy |

A structural and stable metal allow with low costs due to wide availability. |

360.0, A360.0, ADC12, 380.0, A380.0, 383.0, 384.0, B390.0, 413.0, A413.0, C443.0, 518.0 |

|

Magnesium Alloy |

A lightweight versatile alloy with great surface detail. |

AZ91D, AM60B, AS41B |

|

Zinc Alloy (ZA) |

Better surface finish and better detail performance |

Zamak-2, Zamak-3, Zamak-5, Zamak-7, ZA-8, ZA-12, ZA-27 |

|

Other |

In addition to the above materials, aluminum, lead, tin, and lead-tin alloys are also often used as die casting materials. |

|

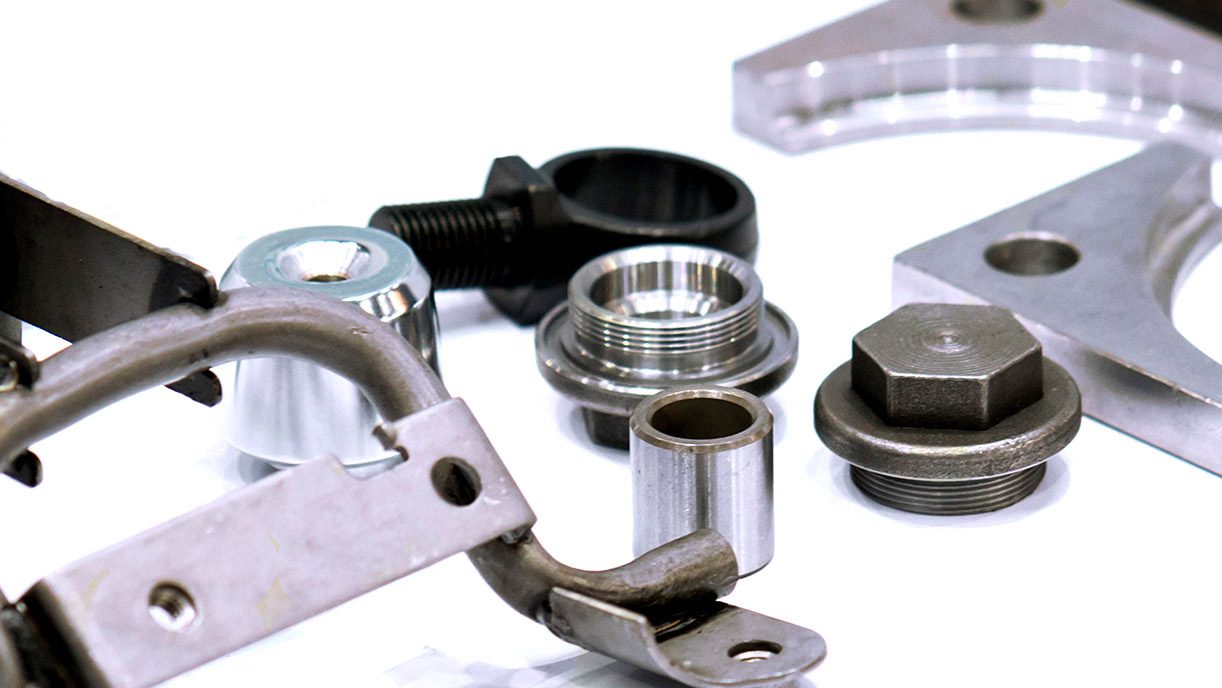

Our Die Casting Products

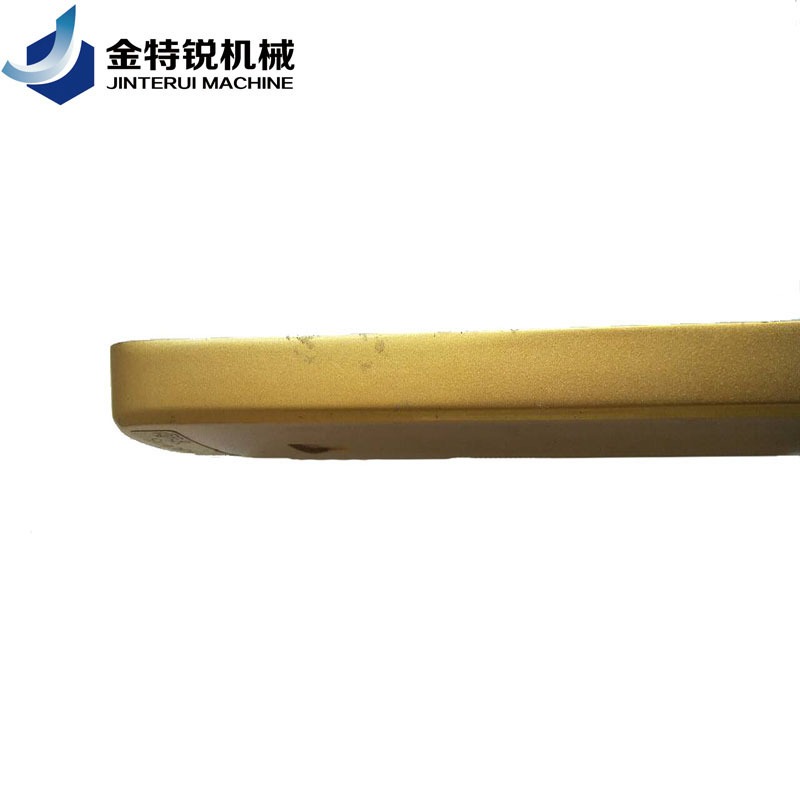

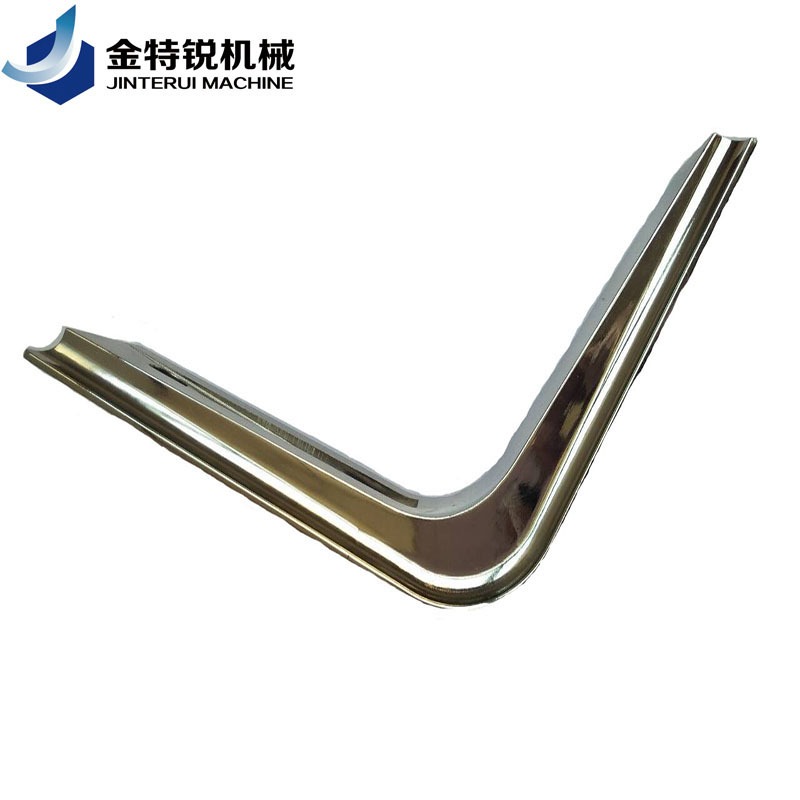

Zamak stainless steel die casting parts

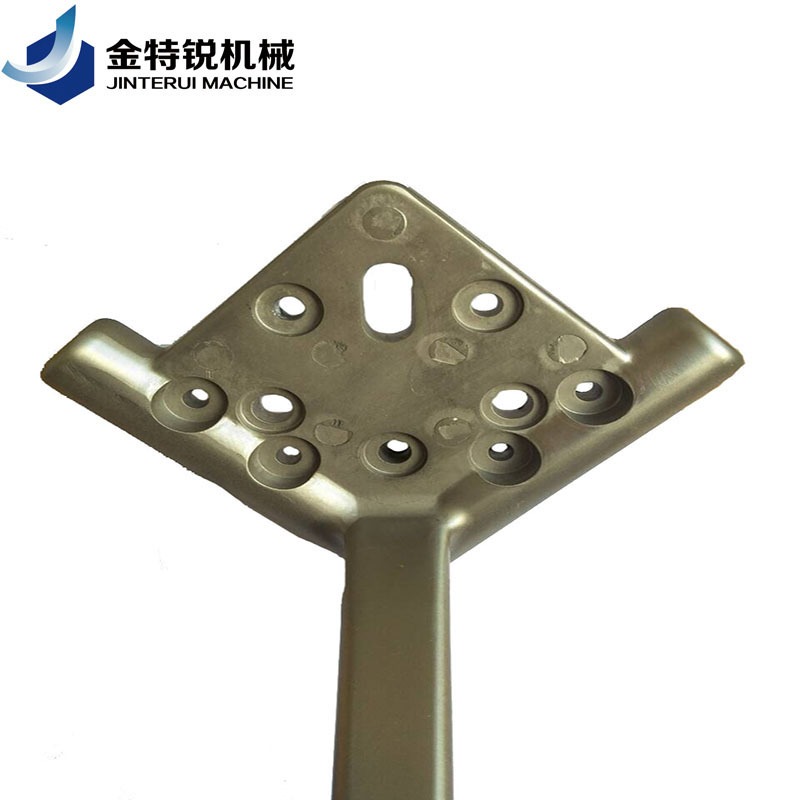

Customized Zamak die casting parts

Custom polished Zamak die casting parts

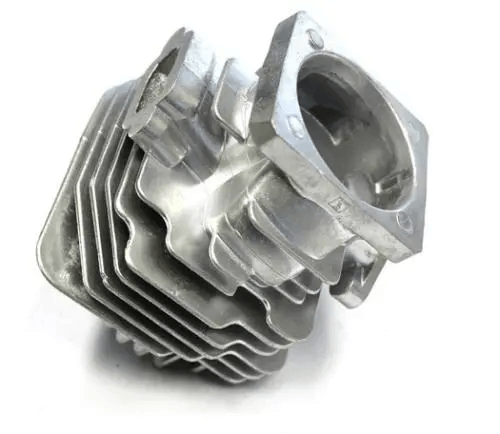

Die casting aluminum parts

Die casting and CNC machining motor parts

CNC milling and die casting car parts

Types of Die Casting Available From JTR

Hot Chamber Die Casting

Also known as gooseneck casting, the hot chamber is the most popular die casting process. A chamber of the injection mechanism is immersed in molten metal and a “gooseneck” metal feed system brings the metal into the die cavity. Hot chamber die casting machines are used for alloys of zinc, tin, and lead.

Cold Chamber Die Casting

Cold chamber die casting is often used to minimize machine corrosion. The molten metal is ladled into the injection system directly, eliminating the need for the injection mechanism to be immersed in the molten metal.

Types of Pressure Die Casting

At JTR Machine, we can provide high-pressure die casting or low-pressure die casting according to your production needs to ensure product quality. High-pressure casting uses a hydraulic cylinder to drive the injection head to press the metal liquid into the mold cavity at high speed. Because it uses oil pressure and the pressure is high, it is commonly known as high-pressure casting; while low-pressure casting uses air pressure to hydraulically press the metal into the mold cavity, The air pressure is generally 0-2Kg/cm2, so it is generally called low-pressure casting.

| Low Pressure Die Casting | High Pressure Die Casting |

| Lower pressure, generally less than 0.08MPa | High pressure, up to several hundred MPa |

| The molten metal flows relatively smoothly | Molten metal flows faster in the cavity |

| The cavity can be metal, sand, etc. (lower requirements for cavity materials) | The cavity can only be metal |

| Can produce small and medium castings and large castings | Usually used to produce small and medium-sized castings |

| Castings can be heat treated | No or incomplete heat treatment strengthened castings |

Die Casting Price

- Different die casting mold processing equipment will also affect the price.

- The material side of the die casting mold has a great influence on the price of the die-casting service. Some die castings have special requirements, so it is also very important for the selection of die steel. Although they can be made, the price of different materials can vary by 20% to 30%.

- Different die casting equipment also has an impact on the price. Different production equipment has different production capacity, labor cost and other expenses.

If you are looking for a low die casting price, please do not hesitate to contact us for a quote!

Why Choose JTR’s Die Casting Service?

The high degree of complexity – Die casting produces close tolerance parts that are durable and dimensionally stable.

Strength — Die cast parts are typically stronger than injection molded parts and more resistant to high temperatures. Wall thicknesses of parts can be thinner than for most other manufacturing processes.

Precision — Die Casting offers tolerances ranging from +/-0.003″ – 0.005″ per inch, and even as tight as +/- .001” depending on customer specs.

Material versatility — A wide range of Al, Zn, and Mg alloys.

Cost-effective — Stamping and die casting integrated installation. This can save installation time. And we pay for the assembly fee, you do not need to pay for the assembly fee.

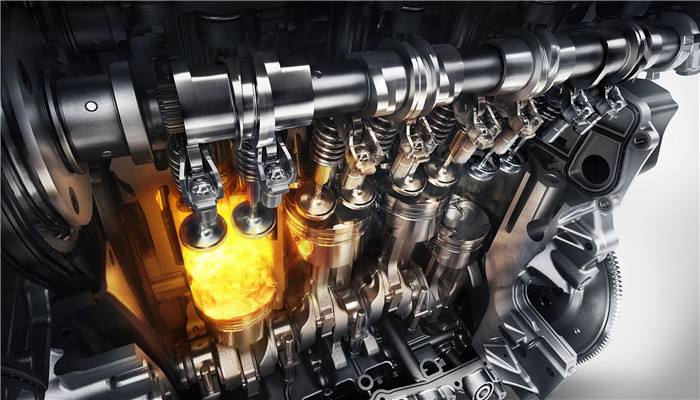

What is Die Casting?

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminum, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

Features of Die Casting

Die casting is a casting method in which molten alloy liquid is poured into a press chamber, the cavity of a steel mold is filled at high speed, and the alloy liquid is solidified under pressure to form a casting. The main characteristics of die casting that distinguish it from other casting methods are high pressure and high speed.

- In the die-casting process, the molten metal fills the cavity under pressure and crystallizes and solidifies at a higher pressure. The common pressure is 15-100 MPa.

- The molten metal fills the cavity at a high speed, usually 10-50 meters per second, and some can exceed 80 meters per second (the linear velocity of the cavity through the inner gate—the inner gate speed), so the filling of the molten metal The molding time is extremely short, and the cavity can be filled in about 0.01-0.2 seconds (depending on the size of the casting).

Die casting is a precision casting method. Die castings made by die-casting have very small dimensional tolerances and high surface accuracy. In most cases, die-casting parts can be assembled and applied without turning, and threaded parts can also be cast directly.

Application Industries

Aerospace & Automotive Components

Die casting works well for Die casting is very suitable for manufacturing automotive and aerospace application parts from high-strength aluminum or lightweight magnesium.

Complex Thin Wall

Many companies use die casting to make complex thin-wall enclosures.

Plumbing Fixtures

Die-cast fixtures offer high-impact strength and are easily plated for plumbing fixtures.

Choose Die Casting or CNC Machining?

Die Casting and CNC Machining are both for producing high-quality products. To make your products have excellent performance and low prices, JTR can provide both die-casting and CNC machining services.

| Die Casting | CNC Machining |

| Suitable for mass production of a large number of products | Suitable for new product development and model changes |

| Suitable for mass production of small and medium die-casting products | High processing accuracy, mass production will not affect product accuracy |

| The surface of the casting is flat, and the size consistency is better | Suitable for multi-variety, small batch production |