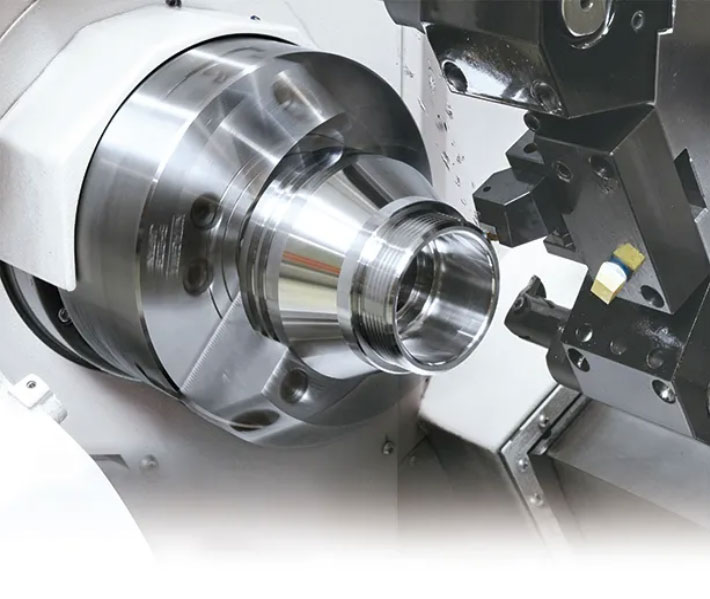

Precision CNC machining is the process of manufacturing dimensionally accurate parts. With the development of advanced technology and the continuous improvement of technology, it is very important to select the correct material to achieve the precision of CNC machining. This article will introduce the list of raw materials suitable for precision CNC machining.

Precision CNC machining is the process of manufacturing dimensionally accurate parts. This is often used to manufacture complex components in industries such as aerospace, automotive, modern electronics, etc. With the development of advanced technology and the continuous improvement of technology, it is very important to select the correct material to achieve the precision of CNC machining.

Generally speaking, materials used for precision CNC machining need to have dimensional stability, machinability, and ease of processing, corrosion resistance, impact resistance, and other properties. Some materials meet these criteria, however, not all materials are suitable for your application.

Several materials meet these criteria, however, not all materials are suitable for your application. To choose the right materials, it is important to understand their properties and uses. This article presents a list of raw materials that have these properties and are suitable for precision CNC machining.

CNC Machining Materials – Stainless Steel

Stainless steel (SS) is undoubtedly the most commonly used material in precision CNC machining. The term stainless steel covers a wide range of grades such as SS303, SS304, SS316, etc. All materials differ in the SS range by the amount of dopant material added.

In SS303, sulfur is added for better machinability and a rust-free experience. In SS304, the addition of nickel and chromium can enhance toughness and reduce magnetic properties. However, SS316 uses molybdenum to achieve marine-grade stainless steel. SS316 has high weldability, workability, and corrosion resistance. All the above grades of stainless steel are suitable for precision CNC machining.

CNC Machining Materials – Steel

Steel is one of the metal alloys used for precision CNC machining. It has high dimensional stability and workability. Precision CNC machining requires consideration of different grades of steel, which include mild steel, carbon steel, plain carbon steel, low alloy steel and high alloy steel. Mild steel has good ductility, while carbon steel has high strength. Plain carbon steel is the first choice for low ductility and high strength applications. Alloy steel can be formed by doping molybdenum, nickel and chromium as required. Therefore, alloy steels can be used in applications that require properties such as corrosion resistance, durability, weldability, etc.

CNC Machined Materials – Brass

Brass has excellent machinability, which helps to obtain maximum accuracy of the desired dimensions. Brass provides precise tolerances during machining and post-finish machining. Different grades of brass are available for different requirements.

Commonly used brass grades are C35300 and C36000. Brass C35300 has excellent corrosion and wear resistance. However, the C36000 is suitable for parts that require higher precision. It has superior machinability, so applications requiring dimensional stability and surface finish can use this grade of material.

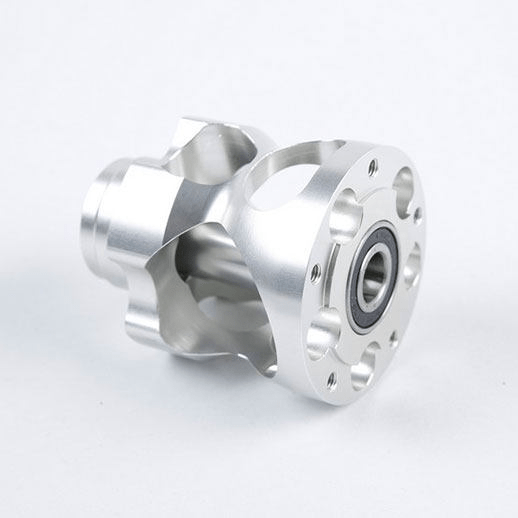

CNC Machining Materials – Aluminum and Aluminum Alloys

Aluminum is a lightweight material. It is non-magnetic, which makes aluminum suitable for CNC machining. It has a low coefficient of deformation, high dimensional stability, and impact resistance. As a result, aluminum and aluminum alloys maintain precise dimensions under different conditions such as temperature fluctuations, external shocks, etc. Like stainless steel, various grades of aluminum are also popular. Here are some commonly used ones:

- Aluminum 6061: It is the most popular aluminum variety. It has excellent mechanical properties such as high strength, corrosion resistance, high toughness, and weldability.

- Aluminum 7075: Has good fatigue resistance, so it can be used in high-strength industrial applications. Aircraft wings and molten glass are made from this material.

- Aluminum 2024: High heat, impact, and fatigue resistance, so it is used in military and aerospace applications.

- Aluminum 5052: Strong chemical and corrosion resistance. It is not heat treatable, so it can be used in marine applications.

- Aluminum 6063: It is a heat treatable alloy with high weldability and durability for the manufacture of complex parts.

CNC Machined Materials – Copper

Copper is a non-ferrous material that is not susceptible to corrosion. It is electrically conductive and durable, making it suitable for precision machined electronic components. Copper alloys such as brass, bronzes, nickel-silver, and copper-nickel alloys are widely used.

CNC Machined Materials – Titanium

Titanium is very immune to heat and oxidation. It is also very compatible with biological factors. Its biocompatibility makes it ideal for use in key areas such as the medical, chemical, and aerospace industries.

Although it is difficult to machine, its machinability can be improved by CNC machining. Commonly used titanium grades are Titanium 1-4, which provide progressively increasing tensile and yield strengths. Grade 5 titanium is suitable for temperature resistance, while grade 9 titanium is popular for its suitability to ensure durability.

If you want to learn more about CNC machining material options, check out this previous JTR article. If you want to customize your CNC parts or CNC products, please contact us, we will complete your products in the shortest time.