CNC Turning Titanium Parts

Titanium is a high-performance material used in the aerospace field. Its lightweight, high strength, good toughness, and corrosion resistance are the most significant characteristics. In addition, it is also widely used in general industries, construction, four-and two-wheeled vehicles and products for daily use, etc. Among many metal materials, titanium alloy is the only material that has high strength, low density, excellent fatigue resistance and corrosion resistance, and low elastic modulus.

Titanium alloy is hard to machine at high temperatures (above 600℃), it would react with oxygen, nitrogen, hydrogen, etc., and deteriorates the material, making subsequent machining relatively difficult. While it is still an important role in many industries.

About the CNC Turning Material — Titanium

Titanium ores are mainly ilmenite and rutile. The two most prominent advantages of titanium are high specific strength and strong corrosion-resistance, which determines that titanium must have broad application prospects in aerospace, weaponry, energy, chemical industry, metallurgy, construction, and transportation. The abundant reserves provide a resource base for the wide application of titanium.

| Yield Strength | Elongation at Break | Hardness | Density | Max Temp |

| 120,000 PSI | 10% | Rockwell C30 | 0.16 lbs / cu. in | 3000°F |

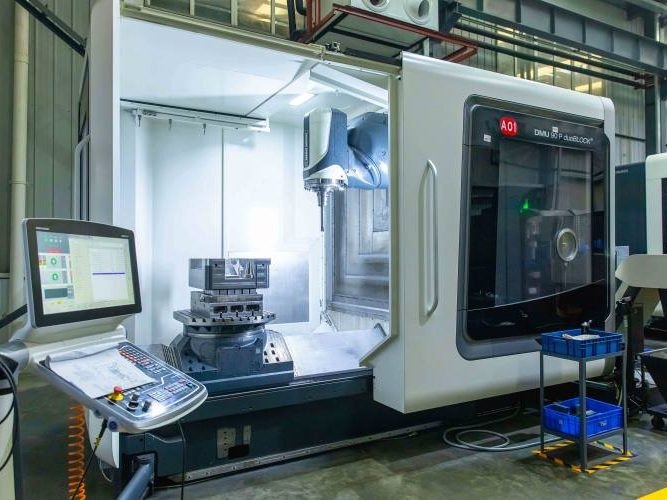

China’s top Class Titanium CNC Turning Manufacturer

Manufacturing a wonderful turned titanium part is hard for many CNC manufacturers, while there are some excellent producers in China they are performing good on it, JTR is a professor Titanium CNC Turning, we have at least 70 CNC machining centers, mills, lathes, and drills are all available, with 10 years experience in CNC, our team is very experienced in support design suggestions. Our intention is usually to satisfy our buyers by offering a great rate, good quality, competitive price for CNC turning components service.

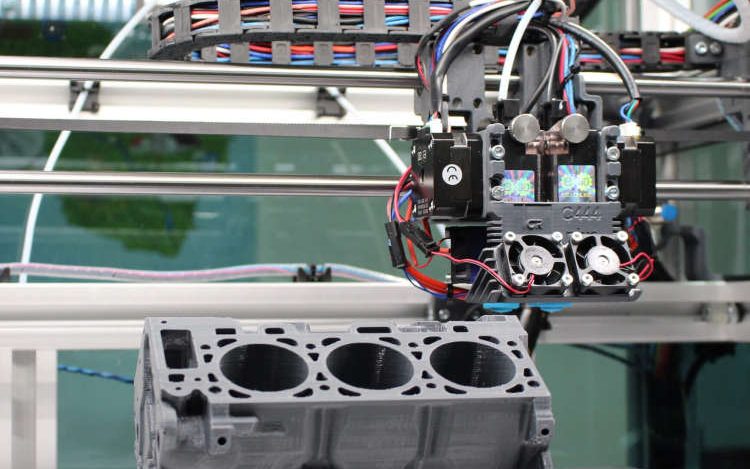

The Characteristics of Machining Center Processing Titanium Alloy

(1) The machining center can process multiple parts at the same time to improve production efficiency.

(2) It can improve the accuracy of parts processing and the consistency of products is good. The machining center has a numerical control tool compensation function, which can obtain the machining accuracy of the machine tool itself.

(3) It has a wide range of adaptability and greater processing flexibility.

(4) It can realize multiple functions in one machine. The machining center can perform a series of processing such as milling, drilling, boring, and tapping.

(5) Accurate cost calculation can be carried out to control the production schedule.

(6) There is no need for special fixtures, which can save costs and shorten the production cycle.

(7) It can greatly reduce the labor intensity of workers.

(8) CAD/CAM software such as UG can be used for multi-axis machining.