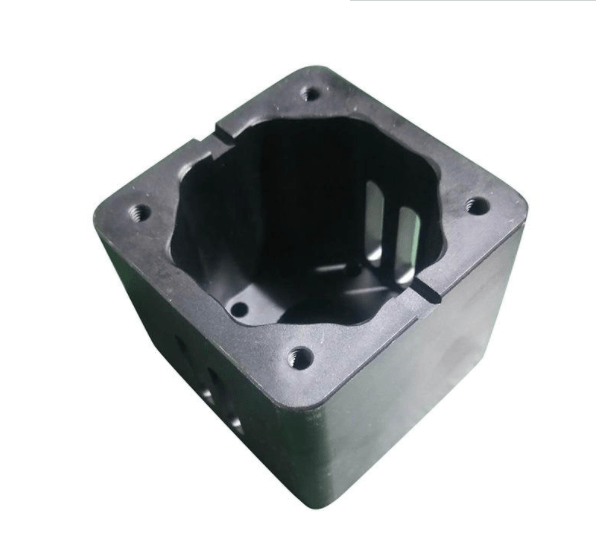

CNC Turning Steel Parts

As the most commonly used material in manufacturing, steel has always been the material of choice for machining parts. As the most commonly used material in manufacturing, steel has always been the material of choice for machining parts. As a type of CNC Machining, using CNC Turning is the most common manufacturing process for custom rigid parts.

Why Choose JTR CNC Turning Steel?

At JTR, we have extensive knowledge and expertise in CNC turning, and years of machining experience have led us to have full confidence in CNC steel.

Turning of all parts will be done on our CNC lathes. A wide range of lathes offers many options for our customers and us as subcontractors and collaborators. So we can produce complex assemblies and simpler parts.

Like CNC milling, CNC turning is a machining process that involves chip evacuation, and our always-optimized and up-to-date machines allow us to provide our customers with high-quality turned workpieces. We turn workpieces from materials such as black steel, aluminum, stainless steel, plastic, brass, and copper.

CNC Turning Materials for Steel Parts

Steel 1018

Generally referred to as light steel, 1018 is very weldable as well fit to appear solidifying procedures such as carburizing. Once carburized, this product is generally utilized for gears, worms, mold, and mildew parts.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm^3) |

| 310 | 78 | 20 | 131 | 7.87 |

Steel 4130

When contrasted to normal moderate steel, this kind is commonly known as alloy steel due to its increased degrees of alloying components. This alloy includes chromium and also molybdenum as reinforcing aspects. These components significantly boost its mechanical homes. Applications can consist of taps, drills, and also aircraft engine mountings.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm^3) |

| 310 | 78 | 20 | 131 | 7.87 |

Steel 4140

The properties of steel 4140 and 4130 are similar, but the carbon content has been increased. The extra carbon increases its strength and gives it better hardening properties. Chromium is also added to improve corrosion resistance. Applications for Steel 4140 include thin-walled pressure vessels, spindles, and high-strength bolts.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm^3) |

| 655 | 80 | 25.7 | 197 | 7.85 |

Steel 4140 PH

4140PH steel is a pre-hardened version of 4140 steel with excellent mechanical strength and hardness properties. Its pre-hardening eliminates the need for post-processing heat treatment. This is ideal if you are concerned that the heat treatment of the part will cause unacceptable deformation of the finished part. Typical applications include shafts, mandrels, and dies.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm^3) |

| 1241 | 80 | 14 | 429 | 7.8 |

Steel A36

Inexpensive and easy to weld, A36 steel is a very common grade of mild steel. It is commonly used in areas such as manufacturing and steel structure support.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm^3) |

| 250 | 79.3 | 20 | 119 | 7.85 |

Steel 4340

This steel is a high-strength, low-alloy metal. It has excellent toughness and strength and retains these properties at relatively high temperatures. Typical applications include gears, shafts, and other structural components.

| Tensile Strength, Yield (MPa) | Shear Modulus (GPa) | Elongation at Break (%) | Hardness (Brinell) | Density (g/cm^3) |

| 470 | 74 | 22 | 217 | 7.85 |

Advantages of CNC Turning Steel Parts

- CNC turning is an automated work mode, which greatly improves work efficiency.

- CNC turning is an automated work mode, which greatly improves work efficiency CNC turning in an automated process generally has much lower error rates and higher part quality than manual turning.

- CNC turning is an automated work mode, which greatly improves work efficiency CNC turning is completely suitable for the production of small and medium-sized parts of 50-1000 scales.

- CNC turning is an automated work mode, which greatly improves work efficiency Save labor costs, resulting in an overall reduction in parts costs.

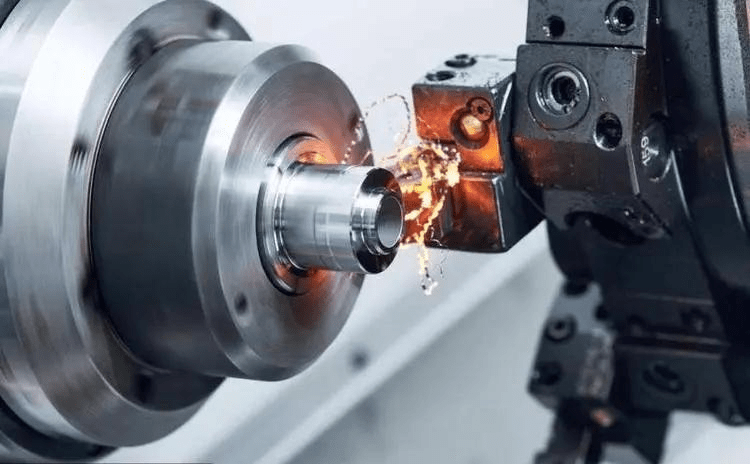

What is CNC Turning?

Turning is a machining method in which a workpiece is rotationally machined using a cutting edge with a specific geometry. Usually, the workpiece rotates, and the tool with a single cutting edge moves along the machined surface. Compared with boring and milling, turning is the most common machining method in modern machining methods.

New, turning problems are limited almost exclusively to chip formation and machining costs. Controlled chip flow and chip breaking in turning means not only that the material being removed is removed from the machined area, but the chips must break in a controlled manner to remove as much cutting heat as possible from the cutting process.

Materials Finishes

- The finish of steel is similar to that of stainless steel, generally shiny in appearance and slightly darker than aluminum alloys.

- CNC turning steel parts can be media blasted again after machining or electropolished to a variety of surface finishes.

Process Characteristics of CNC Turning

- It is easy to ensure the positional accuracy of each machining surface of the workpiece

- The cutting process is relatively stable, avoiding inertial force and impact force, allowing the use of larger cutting amount, high-speed cutting, which is conducive to improving productivity

- Suitable for the finishing of non-ferrous metal parts

- When the surface roughness of non-ferrous metal parts is large and the Ra value is small, it is not suitable to use grinding, but turning or milling is required. High quality can be achieved when fine-turning with diamond turning tools.

Application of JTR CNC Turning Steel Parts

Medical Instruments

Airplane

Military

Fishing

Auto Industry

Electrical Appliances

communication Equipment

Machine Made

Industrial Equipment

Try JTR Machine Out Now In Just A Few Steps

Upload your CAD files

Multiple designs for different parts can be imported at the same time to produce a single quote. In less than a minute, a detailed cost estimation appears on the screen.

Choose the process

First, select the manufacturing process you require. You can then choose from over 70 materials, both metals and plastics, and from a wide range of finishes and certifications.

Order your parts online

Once you have selected the required options, all you need to do is confirm the order and pay for it on the secure payment platform. Your design will be analyzed by engineers.

Receive your parts

Within a short amount of time, you will receive the parts you ordered directly to your shipping address. You can track your package at any time in your personal account.