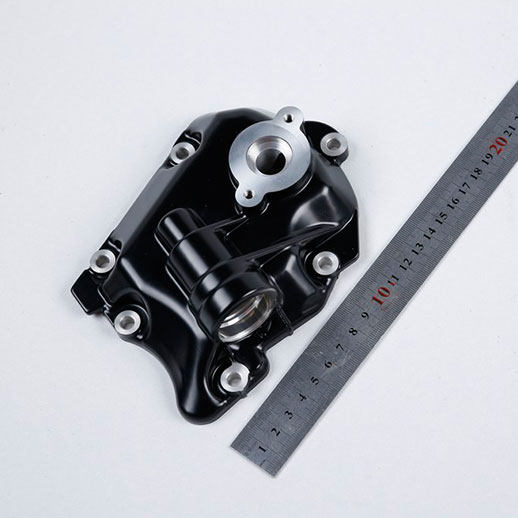

CNC Milling Car Parts For Motor

- Part Size: 120 * 100(mm)

- Main Material: Aluminum ADC12

- Surface Treatment: Stoving Varnish

- Process: CNC Machining

- Application fields: Automotive, Automation, Test systems, Sensors, Medical, Sports, Consumer, Home appliance, Electronic, Pumps, Computers, Power and energy, Architecture, Printing, Food, Textile machinery, Optical, Lighting, Security and safety, AOI, SMT equipment, etc

Description

Available Types of Aluminum

We can provide many different types of aluminum materials for the CNC machining of your parts. Depending on your product expectations, you can choose from the following types of materials for the CNC machining of your parts.

Aluminum 5052: good workability, medium static strength, high fatigue strength, good weldability, and very good corrosion resistance, especially in marine atmospheres. It also has a low density and excellent thermal conductivity similar to other aluminum alloys.

Aluminum 6061: the most common general-purpose aluminum grade and is typically used for auto parts, bicycle frames, sporting goods, frames for RC vehicles, and more. Similar to other aluminum alloys, it has a good strength-to-weight ratio and is naturally resistant to atmospheric corrosion.

Aluminum 6063: can be softly anodized to create an aesthetically pleasing, colored finish for visual architectural and building applications. Common uses for 6063 AL include window frames, door frames, roofs, and sign frames since high strength is not the most important factor. It is also used for electrical components and conduits, pipe and tube for irrigation systems, architectural & building products, railings, furniture, appliances, boats, and motor vehicles.

Aluminum2017: heat-treatable wrought alloy with intermediate strength. It is stronger than aluminum/aluminum 2011 but harder to the machine. Workability is fair with ductility and formability better than aluminum/aluminum 2014. Arc and resistance weldability of this alloy are satisfactory while corrosion resistance is fair. an essential material in various industries such as aerospace, marine, construction, and automobile.

Aluminum7075: slightly larger than pure aluminum at 2.81 g/cm3 (0.102 lb/in3), and it can also be strengthened using the heat treatment process (the most common temper being 7075-T6). The density of 6061 aluminum alloy is 2.7 g/cm3 (0.0975 lb/in3), or about the same as pure aluminum metal.

Product Surface Finishing

In order to have an excellent surface for your parts, we can provide the following surface treatment services according to your requirements.

- Anodizing

- Bead Blasting

- Hard Coat Anodizing

- Heat-treating

- Induction Heat Treating

- Laser Etching

- Pad Printing, Painting

- Parkerizing

- Plating

- Polishing

- Powder Coating

- Precious Metal Plating

Why Choosing Us?

JTR can provide customers with various types of alloy machining parts, including aluminum, stainless steel, bronze, etc. When parts need to be processed into complex shapes or are not able to be processed through traditional ways, it is time for a CNC machining solution. Our aluminum parts own Strong strength and excellent performance, which made an appearance in the Automobile and motorcycle industry. According to your project, we are capable of making the cost in the best use, and providing you various Parts, accessories, hardware with the best quality as well as acceptable tolerance, and we also offer the best surface finishing service to eliminate defects from the machining process.