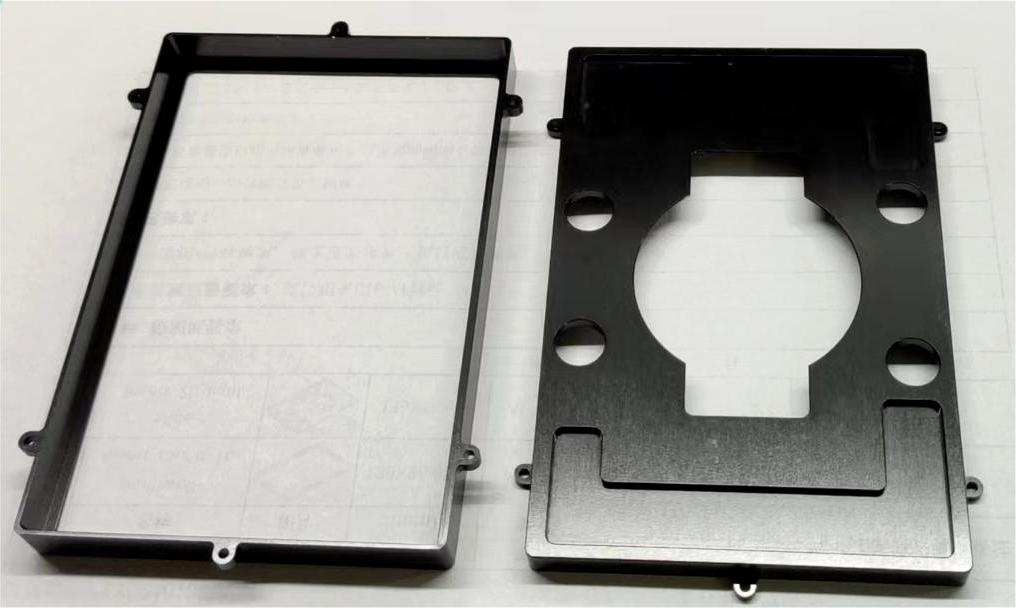

CNC Milled Aluminum Parts with Black Anodizing

- Material: Al6061

- Size: 139X96.6X12mm,139X96.6X8mm

- Process: CNC milling

- Surface treatment: black anodizing

What are the Benefits of Black Anodized Aluminum?

Black anodized aluminum offers several benefits:

- Enhanced Durability: Anodizing creates a hard, protective layer on the surface of aluminum, increasing its resistance to corrosion, scratching, and wear. This layer also makes the aluminum more durable in harsh environments.

- Aesthetic Appeal: The black color achieved through anodizing gives aluminum a sleek, modern appearance. This makes it popular for various applications where aesthetics are important, such as in consumer electronics, automotive parts, and architectural elements.

- UV Resistance: Anodized aluminum is more resistant to fading and degradation from exposure to ultraviolet (UV) radiation compared to untreated aluminum. This makes it suitable for outdoor applications where prolonged exposure to sunlight is expected.

- Electrical Insulation: The anodized layer acts as an electrical insulator, which can be beneficial in electronic applications where electrical conductivity needs to be controlled or minimized.

- Temperature Resistance: Anodized aluminum can withstand high temperatures without losing its color or other properties, making it suitable for use in applications exposed to heat.

- Low Maintenance: Black anodized aluminum requires minimal maintenance due to its enhanced durability and resistance to corrosion and wear. It can be easily cleaned with mild soap and water.

Overall, black anodized aluminum offers a combination of aesthetic appeal, durability, and functional benefits, making it a popular choice for a wide range of applications across industries.

What is the Difference Between Black Anodize and Hard Black Anodize?

The primary difference between standard black anodize and hard black anodize lies in the thickness and hardness of the anodized layer.

| Aspect | Standard Black Anodize | Hard Black Anodize |

| Thickness of Anodized Layer | Typically 0.5 to 3 microns (0.00002 to 0.0001 inches) | Typically 25 to 50 microns (0.001 to 0.002 inches) or thicker |

| Hardness of Surface | Moderate hardness | Greater hardness |

| Durability | Moderate resistance to wear and corrosion | Enhanced resistance to wear and corrosion |

| Production Process | Similar to standard anodizing process | Similar to standard anodizing process, with modifications for thicker layer |

| Wear Resistance | Moderate | High |

| Corrosion Resistance | Moderate | High |

| Common Applications | Consumer electronics, architectural elements | Aerospace components, automotive parts, military equipment |

| Advantages | Aesthetic enhancement, moderate protection | Enhanced durability, hardness, and corrosion resistance |

| Disadvantages | Limited wear and corrosion resistance | Higher cost and longer processing time |

In summary, while both standard black anodize and hard black anodize produce black-colored finishes on aluminum, hard black anodize offers greater durability, hardness, and corrosion resistance due to its thicker and denser oxide layer. Hard black anodize is commonly used in applications where enhanced wear resistance and durability are required, such as in aerospace, automotive, and military components.

Does Black Anodized Aluminum Rust?

No, black anodized aluminum does not rust. Anodizing creates a protective oxide layer on the surface of aluminum, which enhances its corrosion resistance. This oxide layer acts as a barrier, preventing moisture and other corrosive substances from reaching the underlying aluminum. As a result, black anodized aluminum is highly resistant to rust and corrosion, making it suitable for outdoor and marine applications where exposure to moisture is common. However, it’s important to note that while anodized aluminum is highly resistant to corrosion, the underlying aluminum can still corrode if the anodized layer is damaged or compromised. Regular maintenance and care can help prolong the lifespan of black anodized aluminum surfaces.