After continuous updating and iteration of technology, the production method of products has also developed from traditional CNC machining (subtractive manufacturing) to 3D printing (additive manufacturing).

Of course, 3D printing has strong advantages, so does it mean that CNC machining will be eliminated? This article will focus on analyzing this question, hoping to answer the same confusion.

What are the advantages of CNC machining?

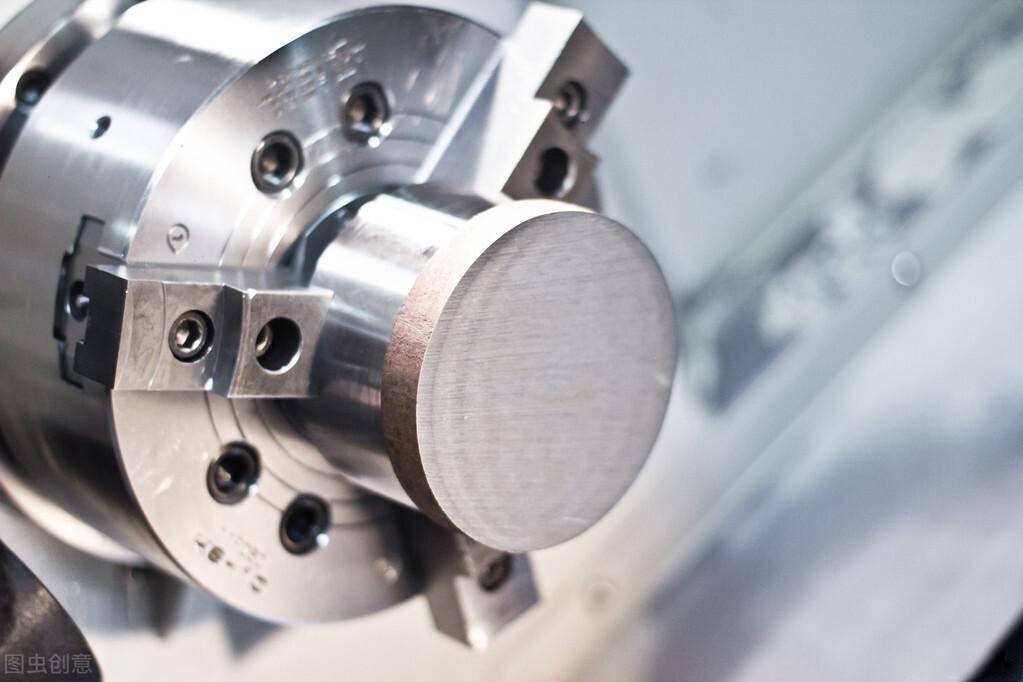

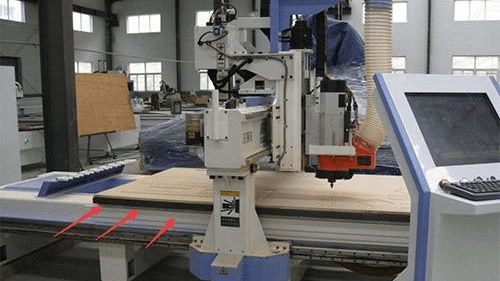

CNC machining is that machining with CNC machining tools. CNC index-controlled machine tools are programmed and controlled by CNC machining language, usually G code.

The CNC machining G code language tells the CNC machine tool which Cartesian position coordinates the machining tool adopts and controls the feed rate and spindle speed of the tool and functions such as tool changer and coolant.

CNC machining has great advantages over manual machining! E.g

- The parts produced by CNC machining are very accurate and repeatable;

- CNC machining can produce parts with complex shapes that manual machining cannot do.

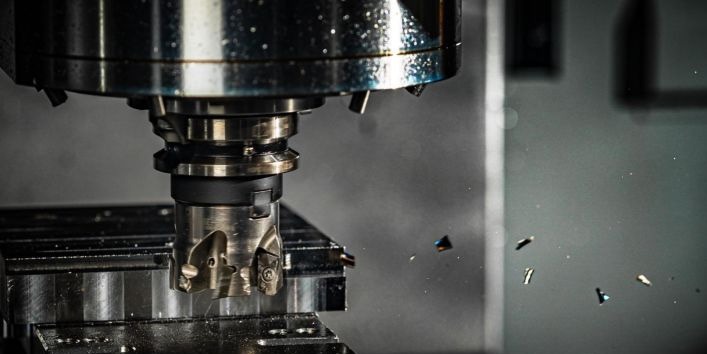

CNC machining technology is now widely used, and most machining workshops have CNC machining capabilities. The most common CNC machining methods in typical machining workshops are CNC turning, CNC milling, and EDM wire cutting.

The CNC milling tools are called CNC milling machines or CNC machining centers. A lathe that performs CNC turning is called a CNC turning center. CNC machining G codes can be programmed manually, but usually, machine shops use CAM (Computer Aided Manufacturing) software to automatically read CAD (Computer-Aided Design) files and generate G code programs to control CNC machine tools.

What are the advantages of 3D printing?

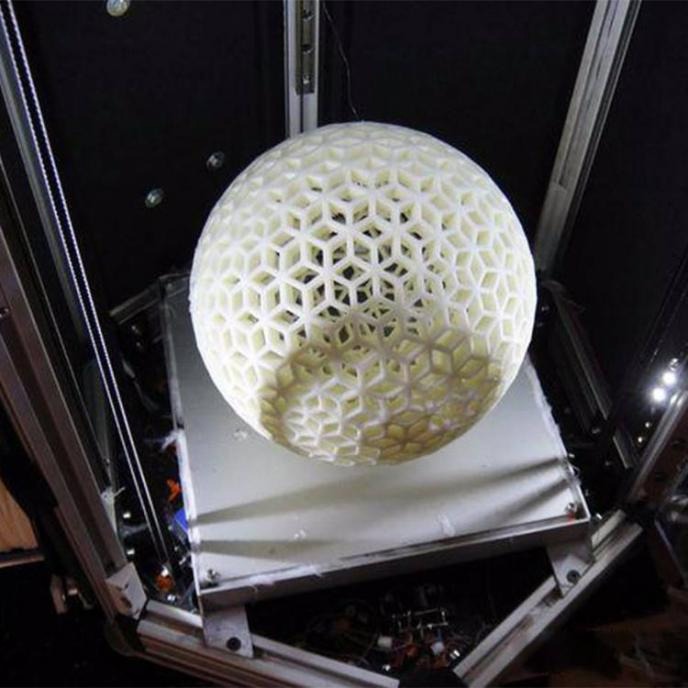

As a new manufacturing technology, 3D printing is hailed by the media as the beginning of the third industrial revolution. So what is 3D printing?

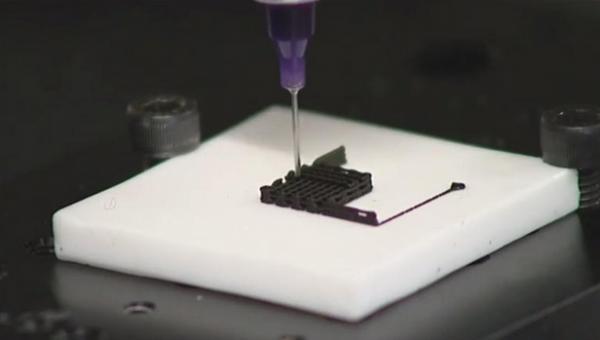

3D printing belongs to a kind of rapid prototyping technology, which is a technology of constructing objects by stacking and accumulating layer by layer based on a digital model file (i.e., “lamination”). Formation”). In the past, it was often used to make models in the fields of mold making, industrial design, etc., but now 3D printing is gradually being used for the direct manufacturing of some products. Especially some high-value products (such as hip joints or teeth, or some aircraft parts).

Advantages of 3D printing technology:

- Save material. There is no need to remove leftovers, which improves the utilization rate of materials and reduces the cost by abandoning the production line;

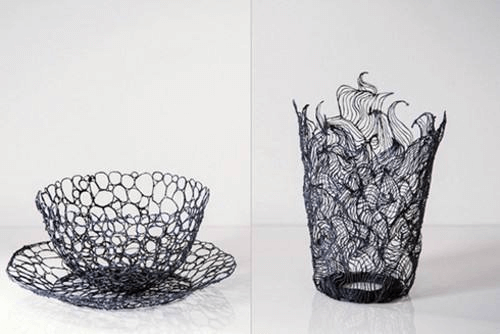

- It can achieve high precision and high complexity and can produce very complex parts that traditional methods cannot produce;

- Without the need for traditional tools, fixtures, machine tools, or any molds, the 3D CAD graphics of any shape on the computer can be directly generated into physical products;

- It can automatically, quickly, directly, and accurately convert the three-dimensional design in the computer into a physical model, and even directly manufacture parts or molds, thereby effectively shortening the product development cycle;

- 3D printing does not require a centralized and fixed manufacturing workshop and has the characteristics of distributed production;

- 3D printing can take shape in hours, allowing designers and developers to leap from the floor plan to solid;

- It can print assembled products, thus reducing assembly costs and even challenging mass production methods.

What is the difference between CNC machining and 3D printing?

If we want to know whether CNC machining will be replaced by 3D printing, we must first know the difference.

Differences in 3D printing and CNC machining materials

3D printing materials mainly include liquid resin (SLA), nylon powder (SLS), metal powder (SLM), gypsum powder (full-color printing), sandstone powder (full-color printing), wire (DFM), sheet (LOM), etc.

Liquid resins, nylon powders, and metal powders account for the vast majority of the market for industrial 3D printing.

The materials used for CNC machining are all pieces of plates, that is, plate-like materials. By measuring the parts’ length, width, height, and wear, the corresponding size plates are cut for processing.

There are more choices of CNC machining materials than 3D printing. General hardware and plastic sheets can be CNC machined, and the density of molded parts is better than 3D printing.

Differences in parts due to molding principles

As we mentioned earlier, 3D printing is a kind of additive manufacturing. Its principle is to cut the model into N layers/N multi-points and then pile them up layer by layer/bit by bit in order, just like building blocks. Same.

Therefore, 3D printing can effectively process parts with complex structures, such as hollow parts, while CNC is difficult to process hollow parts.

CNC machining is subtractive manufacturing. The required parts are cut out according to the programmed tool path through various tools running at high speed. Therefore, CNC machining can only process rounded corners with a certain radian but cannot directly process inner right angles, which must be realized by processes such as wire cutting/sparking. Outside right angle, CNC machining is no problem.

Therefore, parts with inner right angles can be considered for 3D printing.

There is also the surface. If the part’s surface area is relatively large, it is recommended to choose 3D printing. CNC machining of the surface is time-consuming, and if the programming and operator experience is not enough, it is easy to leave apparent lines on the parts.

Some people say that 3D printing uses cake flour to pile up a cake, and CNC is to cut a big cake into small cakes. It is really simple and easy to understand.

Differences in post-processing

There are not many post-processing options for 3D printed parts, generally grinding, oil injection, deburring, dyeing, etc.

There are various post-processing options for CNC machined parts, in addition to grinding, oil injection, deburring, electroplating, silk screen printing, pad printing, metal oxidation, laser engraving, sandblasting, and so on.

There is a sequence of hearings, and there are specialties in the art industry. CNC machining and 3D printing each have their own advantages and disadvantages. Choosing the right processing technology has a crucial impact on your prototype project.

Will 3D printing replace CNC machining?

Although CNC machining exists as an old-fashioned processing technology, after continuous software and hardware optimization, the processing fineness of CNC machining has been greatly improved (especially in post-processing, a variety of surface treatment methods can be used). Although 3D printing has many advantages, CNC machining will definitely not be replaced by 3D printing.

- CNC machining can greatly reduce the number of tooling, and parts with complex shapes do not need complex tooling. If you want to change the shape and size of the part, you only need to modify the part processing program, which is suitable for new product development and modification.

- The machining quality of CNC machining is stable, the machining accuracy is high, and the repeatability is high, which is suitable for the machining requirements of aircraft.

- In the case of multi-variety and small batch production, the production efficiency is high. CNC machining can reduce the time for production preparation, machine tool adjustment, and process inspection, and the cutting time is reduced due to the use of the optimal cutting amount.

- CNC machining can process complex profiles that are difficult to process by conventional methods and even process some unobservable machining parts.

As a high-quality CNC machining service provider in China, JTR receives a large number of orders from customers all over the world every day. This shows that in the production and processing market of products, CNC machining still has a strong advantage. Moreover, the detailed expression that CNC machining can bring to the product is unmatched by 3D printing.