This paper takes stainless steel medical screws as an example, analyzes the problem of insufficient plasticity of parts and high cost of small batch processing, and uses CNC machine tools to make up for the shortage of special machine tools for cold extrusion of threads.

Through the design of supporting fixture and the preparation of NC macro program, the thread processing method is improved to solve the problems of poor rigidity of medical screws and excessive cutting force when turning threads, which provides a reference scheme for the production of small batches of special material screws.

Why is it difficult to process medical screws?

For small batch production of medical screws, CNC machine tools can be used to make up for the lack of special machine tools.

The diameter of medical screw is small, the pitch is relatively large relative to the diameter, and the rigidity is poor. When machining the thread with a forming tool on an ordinary lathe, the cutting resistance increases gradually with the increase of the cutting depth of the tool. Because of the small diameter and long length of the medical screw, even if there is a support method to offset most of the cutting resistance in the process, it is easy to cause the screw deformation and cannot be cut, so it is difficult to process with an ordinary lathe.

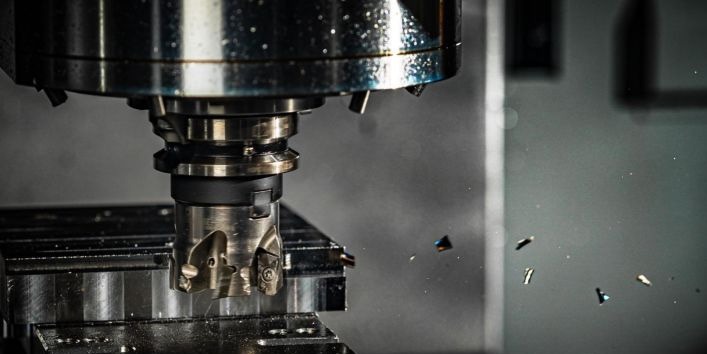

CNC machine tool processing has the advantages of high efficiency and strong adaptability. When macro program is used to turn threads, the contact area between the tool and the workpiece is basically constant, and the cutting resistance will not increase with the increase of the cutting depth of the tool. However, medical screws with poor rigidity are also easy to cause deformation and bending.

In this paper, the processing of medical stainless steel screws is deeply studied, and the problem that stainless steel is not easy to cut is solved through reasonable process settings on the CNC lathe. The problem of insufficient rigidity of thread machining is solved by designing supporting fixture and programming macro program for layered turning.

CNC machining principle of medical screws

According to the geometric characteristics of medical screws, it is the key to process qualified parts to make a reasonable planning for the tool path. CNC machine tools use cemented carbide coated inserts to process threads. The reasonable spindle speed for turning medical screws should be calculated according to the tolerance linear speed v of the inserts, so as to ensure the reasonable service life of the cutters. The calculation formula is

v=πDn/1000

In the formula, v is the linear speed (m/min); D is the turning diameter (mm); N is the spindle speed (r/min).

In the processing of medical screw threads, according to the analysis of the force acting on the tool, the main cutting force consumption accounts for more than 90% of the total power of the machine tool, and the feed resistance consumption accounts for more than 5% of the total power of the machine tool. If the forming tool is used to process the thread on the CNC machine tool, with the increase of the cutting depth of the tool, the contact area between the tool and the workpiece becomes larger, and the cutting resistance also gradually increases, which is likely to cause the vibration, deformation and bending of the parts and lead to the inability to turn.

It can be seen that the traditional forming tools can not meet the processing requirements of medical screws. To improve the processing method, the NC 35 ° profiling turning tool is used, and the macro program is compiled to control the tool tip path to move according to the thread profile. After the tool tip has gone through the profile, it is fed into the turning layer by layer. In this way, the contact area between the tool and the workpiece is basically constant, and the cutting force of the tool in the turning process is basically constant and small, overcoming the growing disadvantage of the cutting resistance of traditional thread forming tools.

1 Selection of tool material

Medical screws are mainly used for the connection of artificial joints and human bones. They need to have a certain strength and corrosion resistance. Therefore, 1Cr18Ni9Ti stainless steel with a certain strength and corrosion resistance and acid and alkali resistance is selected.

This kind of stainless steel has the characteristics of high strength, high plasticity and severe hardening during processing. The cutting resistance of the tool is large during cutting, which is easy to cause serious deformation of medical screws. The tool is easy to form cutting tumors because of its high cutting temperature.

As the medical screw is easy to produce work hardening, which makes its processing difficult, the blade with good heat resistance, wear resistance and thermal conductivity that is not easy to bond should be selected. At the same time, it should be fully cooled during processing. It is reasonable to select a water-based cutting fluid with good heat dissipation.

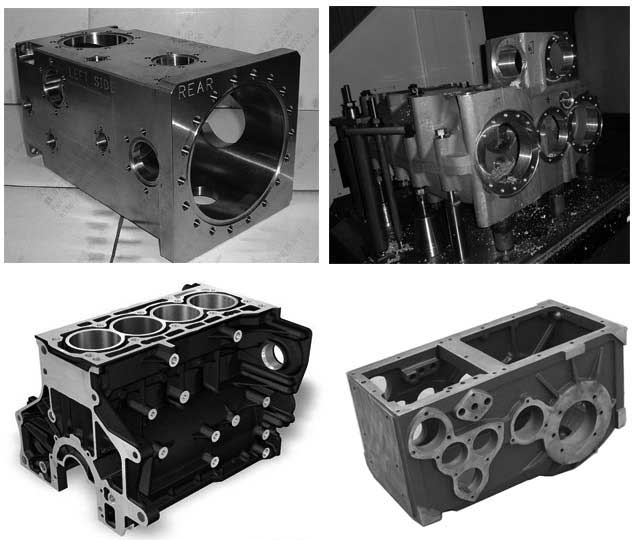

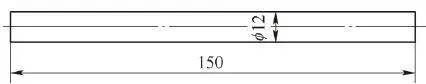

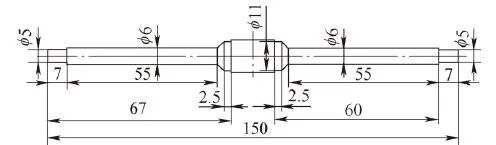

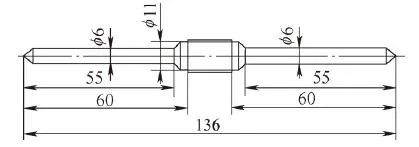

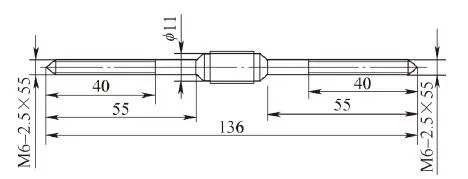

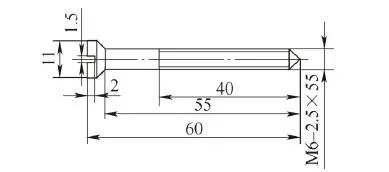

2 Structure and size of medical screw parts

The specification of medical screw shown in the figure below is M6-2.5mm × 55mm, the external diameter is 6mm, the pitch is 2.5mm, the width of the bottom groove is 0.4mm, the width of the top groove is 0.05mm, the tooth angle is 60 °, the length is 55mm, and the maximum diameter of the right end is 11mm. Due to the poor rigidity of the parts and the large screw pitch relative to the diameter, there are certain difficulties in how to enhance the rigidity of the workpiece clamping and the reasonable preparation of the NC macro program.

3 Processing technology

Medical screws are produced in small batches. If the general one clip one top method is used to turn threads, due to the poor rigidity of the workpiece, it is unable to bear the cutting force, which will cause bending deformation in the middle of the workpiece. Therefore, when turning threads, the workpiece must be supported throughout the whole process to ensure that the workpiece is stable and reliable in the support fixture and prevent the workpiece from being unable to process due to deformation. It is necessary to design a special thread turning support fixture to support the screw.

The thread pitch of the part is relatively large. In order to reduce the cutting resistance when cutting the thread and prevent the part from deformation, 35 ° profiling turning tool with carbide titanium carbide coating is selected, and the macro program is compiled by using the path synthesis method to cut the thread layer by layer, which can greatly reduce the cutting resistance when turning the thread and keep it basically constant.

4 The processing of medical screws is shown in the figure. The specific steps are:

① The two parts are processed together, with an additional 15mm left in the middle to facilitate the self centering chuck clamping, and an additional 7mm left at both ends as the process head for drilling the center hole.

② One clamp and one top turn 6mm and 11mm excircles.

③ Clamp 6mm excircle turning to remove the process head, so that the center hole is also removed, and then the two ends of the part can be turned into a complete taper.

④ Clamp 11mm excircle, use support fixture to support 6mm excircle of medical screw, and use macro program to turn thread.

⑤ Cut the two screws that are connected together to ensure the length is even and the size is 60mm.

⑥ Use vertical rotary worktable to clamp on horizontal milling machine, and use saw blade milling cutter to mill 1.5mm wide groove.

Drill center holes at both ends of blanking

Process head for turning excircle

Turning taper after cutting off process head

Support turning thread with fixture

Flatten the length after cutting, and slot on the milling machine

5 Macro programming

Macro programming is the key in all elements of part processing. Now, macro programming is carried out for thread processing on FANUC0i CNC lathe. Macro programming principle: each time the tool determines a point in the thread profile shape and moves a pitch; The tool returns to the starting point, moves a point along the thread profile, and then moves a pitch; After turning the whole tooth shape, the layered feed turning is realized through coordinate system offset, and finally the complete tooth shape is turned.

6 Processing precautions and quality inspection

During the processing of medical screws, the error of the size of the excircle diameter of 6mm should be controlled at about 0.04mm. If the error of the excircle diameter is large, it will result in poor coincidence between the semicircle hole with the diameter of 6mm in the supporting fixture and the excircle of the screw, the supporting role of the fixture will be weakened, and vibration or workpiece deformation will occur during turning. At the same time, the blade must be kept sharp when turning the thread, and the tool cannot be changed in the middle, otherwise the thread may be disorderly buckled.

Use a micrometer to measure the outer circle size of the medical screw with a diameter of 6mm, use a caliper to measure the thread pitch, and use a surface roughness comparator to measure the surface roughness value of the thread Ra3.2 μ M Whether it is up to the standard. After testing, the parts fully meet the size requirements and can meet the use requirements.

Summary

Through the analysis of the principle of medical screw NC processing, the design of medical screw support fixture and macro programming are completed, which realizes the NC processing of medical screws and makes up for many shortcomings of cold extrusion ordinary screws.

Through this method, small batch processing of medical screws can be completed at a lower cost. This method of using CNC machine tools to process medical screws provides a reference for the processing of similar screws with special materials.