What is the difference between a machining center, an engraving and milling machine, and an engraving machine? , I believe that many friends who have just joined this circle will ask. Which processing method can you choose to make your parts most perfectly? This article will tell you the difference between the three of them.

What is An Engraving and Milling Machine?

As the name suggests, it can be engraved and milled. Based on the engraving machine, the power of the main shaft and the servo motor is increased, and the bearing capacity of the bed is increased, and the high speed of the main shaft is also maintained.

The engraving and milling machine is also developing at a high speed, generally called a high-speed machine. It has a stronger cutting ability and very high machining accuracy. It can also directly process materials with a hardness above HRC60. It is widely used in the roughing and finishing of precision molds and molds at one time. , Mould copper electrodes, batch processing of aluminum products, shoe mold manufacturing, fixture processing, and watch eye industry.

Due to its high-cost performance, fast processing speed, and good finish of processed products, it occupies an increasingly important position in the machine tool processing industry.

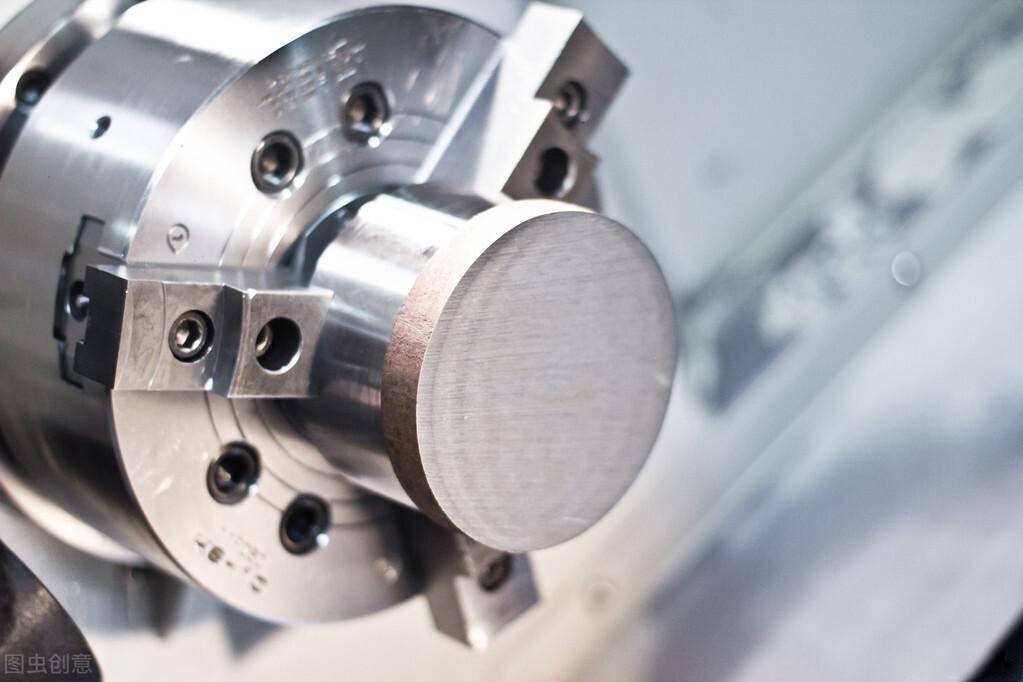

What is a CNC Machining Center?

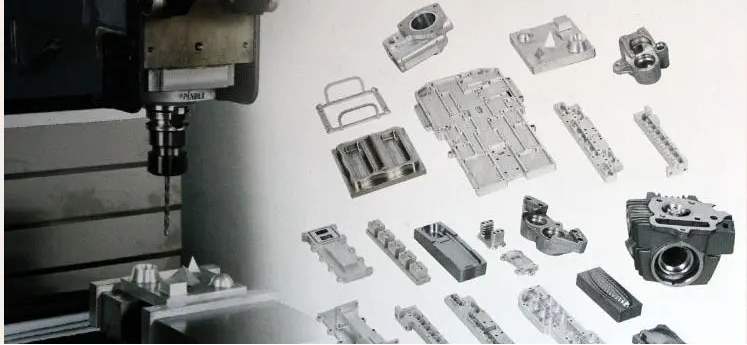

The characteristic of the parts processed in the machining center is that after the parts are clamped once, the CNC system can control the machine tool to automatically select and replace the tools according to different processes.

The CNC machining center can automatically change the spindle speed of the machine tool, the feed rate, the movement path of the tool relative to the workpiece, and other auxiliary functions, and continuously and automatically perform drilling, countersinking, reaming, boring, tapping, Multi-process processing such as milling.

Since the machining center can complete various processes in a centralized and automatic manner, it avoids human operation errors, reduces workpiece clamping, measurement and adjustment time of machine tools, and workpiece turnover, handling and storage time, greatly improving processing efficiency and machining accuracy. .

Therefore, CNC machining centers can provide manufacturers with more convenient and fast CNC machining, and the benefits are also more considerable.

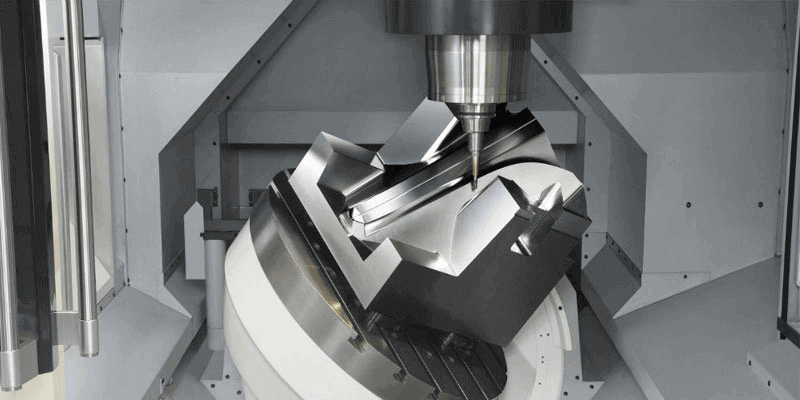

Machining centers can be divided into vertical machining centers and horizontal machining centers according to the position of the spindle in space.

What is An Engraving Machine?

The torque is relatively small, and the spindle speed is high, which is suitable for the processing of small tools. It focuses on the “engraving” function and is not suitable for large workpieces with strong cutting.

At present, most of the products on the market under the banner of engraving machines are mainly for processing handicrafts, and the cost is low. Due to the low precision, they are not suitable for mold development; engraving and milling machines, or machining centers.

The difference between the index data of the engraving machine and the other two processing methods is that the maximum speed of the spindle is different (r/min) (the machining center is 8000; the most common engraving and milling machines are 240000, and the high-speed machine is the lowest 30000); the engraving machine is generally the same as the engraving and milling machine. The engraving machine for high-gloss processing can reach 80,000, but it is not a general electric spindle but an air-floating spindle.

The spindle power is different: the machining center is the largest, ranging from several kilowatts to tens of kilowatts; the engraving and milling machine is second, generally within ten kilowatts; the engraving machine is the smallest.

The cutting amount is different: the machining center is the largest, especially suitable for heavy cutting and roughing; the engraving and milling machine is second, suitable for finishing; the engraving machine is the smallest.

The speed of processing parts is different: because the engraving and milling machine and the engraving machine are relatively light, their moving speed and feed speed are faster than that of the machining center, especially the high-speed machine equipped with a linear motor can move at a maximum speed of 120m/min.

The accuracy of parts that can be manufactured: The accuracy of the three is about the same.

Difference Between CNC Machining Center, Engraving and Milling Machine, and Engraving Machine

CNC Machining Center, Engraving and Milling Machine, and Engraving Machine are all tools used in manufacturing processes, but they have different capabilities and are used for different purposes. Here are the key differences between them:

| Aspect | CNC Machining Center | Engraving and Milling Machine | Engraving Machine |

|---|---|---|---|

| Automation Level | Highly automated | Automated | Manual or semi-automated |

| Machining Operations | Milling, drilling, tapping, etc. | Engraving, milling | Engraving |

| Material Compatibility | Metals, plastics, composites | Metals, wood, plastics, acrylics | Metals, plastics, wood, glass |

| Working Area | Typically larger | Moderate | Smaller |

| Axis Configuration | Multiple axes (3-5 axes) | Typically 3 axes | Typically 2 axes |

| Precision | High | Moderate | Moderate to low |

| Versatility | Versatile, wide range of parts | Limited by engraving capabilities | Limited to engraving applications |

| Common Industries | Aerospace, automotive, electronics | Jewelry making, signage, mold making | Trophy and awards, jewelry making |

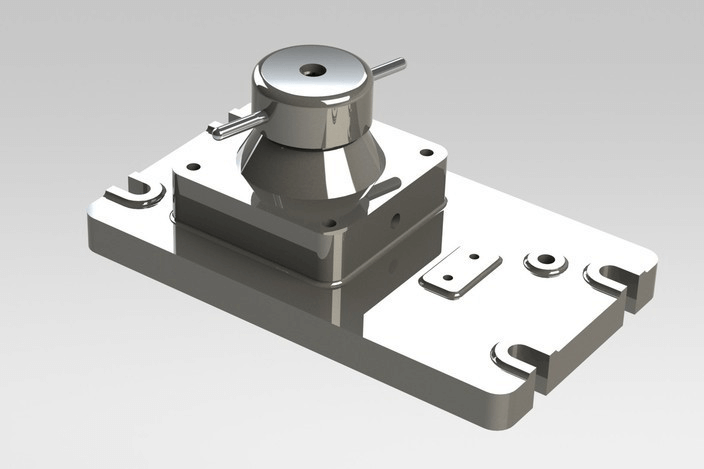

If you are considering the amount of milling, here are the suggestions for you to choose from:

- The CNC milling and machining center is used to complete the processing equipment of workpieces with a large amount of milling.

- The CNC engraving and milling machine is used to complete a small amount of milling, or processing equipment for soft metals.

- The high-speed cutting machine is used to complete the medium milling amount and reduce the grinding amount after milling to the lowest processing equipment.

In summary, while CNC machining centers, engraving and milling machines, and engraving machines all involve material removal processes, they differ in terms of automation level, capabilities, precision, and intended applications. CNC machining centers are highly automated, versatile machines used for various machining operations, while engraving and milling machines and engraving machines are specialized tools primarily used for engraving and small-scale milling operations.