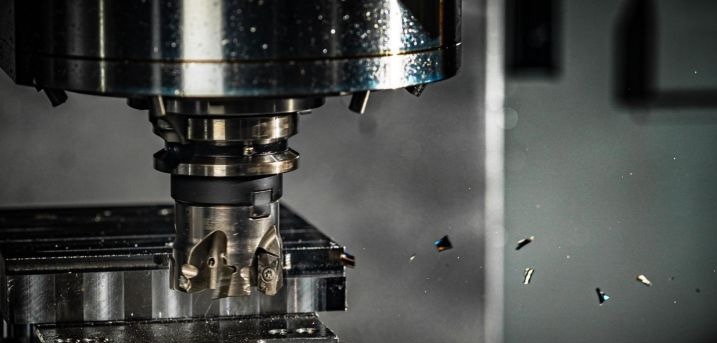

CNC laser cutting, as well as CNC machining, are two machining processes that have distinct toolsets and techniques. But both processes utilize computer numerical control (CNC) systems to automate and control the manufacturing operations enhancing the accuracy, repeatability, and versatility of material processing and shaping. CNC laser cutting can effortlessly slice through a wide range of materials, from metals to fabrics and everything in between.

In this article, we will explore the world of CNC laser cutting, delving into the materials that can be processed, the different types of CNC laser cutting machines, and the significant advantages that make CNC laser cutting a preferred choice in numerous industries.

What materials can be used in CNC Laser Cutting?

CNC laser cutting is a versatile process that can be used to cut a wide range of materials. The suitability of a material for laser cutting depends on its interaction with the laser beam and its ability to be melted or vaporized. Here are some common materials that can be used in CNC laser cutting:

- Metals:

Stainless steel, Mild steel, Aluminum, Brass, Copper, Titanium, Galvanized steel, Gold, and silver (for jewelry applications)

- Plastics:

Acrylic (PMMA), Polycarbonate (PC), ABS (Acrylonitrile Butadiene Styrene), PVC (Polyvinyl Chloride), Polypropylene (PP), Polyethylene (PE), PETG (Polyethylene Terephthalate Glycol), PTFE (Polytetrafluoroethylene)

- Woods:

Plywood, MDF (Medium-Density Fiberboard), Hardwood (such as oak, maple, walnut)

- Fabric and Textiles:

Cotton, Polyester, Felt, Nylon, Leather

- Composite Materials:

Carbon fiber, Fiberglass, Laminates (e.g., plywood, laminate flooring)

- Foam and Rubber:

Foam sheets (e.g., polyurethane foam, EVA foam), Rubber sheets

- Paper and Cardboard:

Cardstock, Paperboard, Corrugated cardboard

What types of machines are used in CNC Laser Cutting?

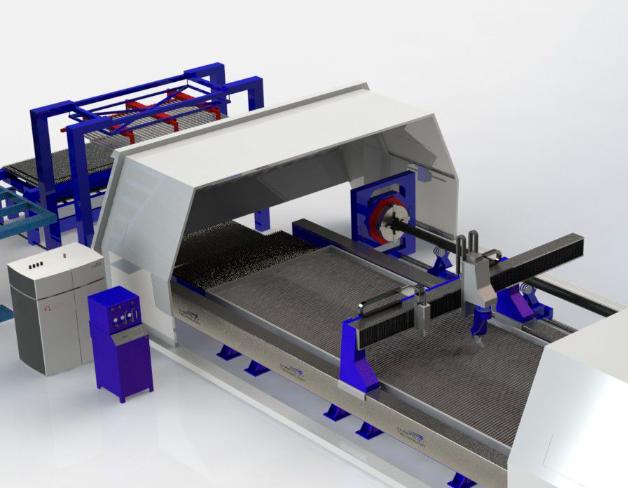

CNC laser cutting machines come in different types, each catering to specific material requirements and cutting applications. Two prominent types are fiber laser cutters and CO2 laser cutters.

CNC CO2 Laser Cutter:

A CNC CO2 laser cutter is a type of computer numerical control (CNC) machine that utilizes a carbon dioxide (CO2) laser as its cutting tool. It is designed to accurately cut or engrave various materials using the thermal energy generated by the focused CO2 laser beam. They are primarily used for non-metal materials such as acrylic, wood, plastics, fabric, and paper. CO2 lasers have a wavelength of around 10.6 micrometers and are well-suited for materials that can be melted or vaporized.

CNC Fiber laser cutter:

A CNC fiber laser cutter is a type of computer numerical control (CNC) machine that utilizes a fiber laser as its cutting tool. It is designed to accurately cut through various materials using the intense laser energy generated by the fiber laser, particularly metals. They are highly efficient and offer excellent cutting precision. Fiber lasers have a wavelength in the range of 1 to 1.1 micrometers and are ideal for cutting metals like stainless steel, mild steel, aluminum, brass, and copper.

Compared to CO2 lasers, fiber lasers have several advantages. They offer higher energy efficiency, allowing for reduced power consumption. Fiber lasers are also more compact and require less maintenance. Additionally, it is well-suited to using CNC laser cutters for metal, as they are less prone to reflection-related issues.

What are the advantages of CNC Laser Cutting?

CNC laser cutting offers numerous benefits that make it a preferred choice in various industries. Here are some key advantages:

- Precision:

CNC laser cutters provide exceptional precision and accuracy, allowing for intricate and detailed cuts. The focused laser beam enables precise control, resulting in clean edges and minimal material distortion. This precision is crucial for industries that require tight tolerances and high-quality finishes.

- Flexibility:

CNC laser cutters offer great flexibility in terms of design and material choices. They can easily handle complex and intricate shapes, enabling the production of highly customized parts and products. The versatility in material compatibility allows for a wide range of applications across different industries.

- Time and Cost Savings:

CNC laser cutting is a highly efficient process that saves both time and money. The automated nature of CNC machines eliminates the need for manual labor-intensive cutting methods. With the ability to rapidly cut through materials, CNC laser cutters significantly reduce production time, leading to increased productivity and faster turnaround times. Additionally, precise cutting minimizes material waste, optimizing material usage and reducing costs.

- Customization:

CNC laser cutting allows for extensive customization possibilities. Whether it’s intricate patterns, personalized designs, or unique shapes, CNC laser cutters can bring creative visions to life. This customization capability is valuable for industries such as signage, art, jewelry, and promotional products where individuality and branding are essential.

- Non-Contact Cutting:

The non-contact nature of laser cutting is a significant advantage. The laser beam does not physically touch the material being cut, minimizing the risk of damage or contamination. This non-contact aspect makes CNC laser cutting suitable for delicate materials or applications where preserving material integrity is crucial, such as in the medical or aerospace industries.

In conclusion, CNC laser cutting is a highly versatile and efficient process that offers numerous advantages in the field of material processing and manufacturing. By employing computer numerical control (CNC) systems and powerful laser beams, CNC laser cutting provides precise, intricate, and high-quality cuts or engravings on a wide range of materials.