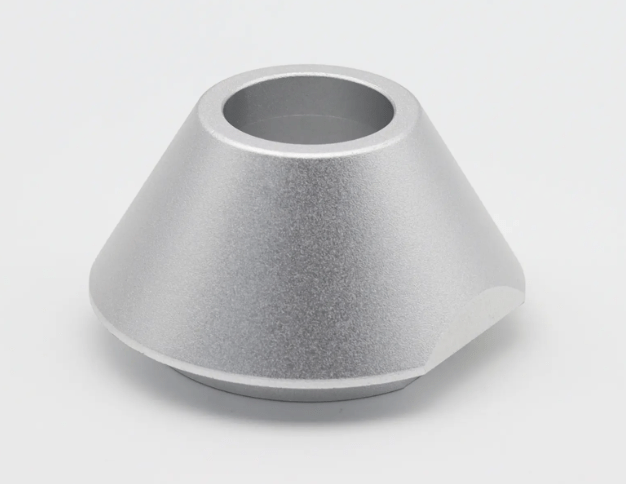

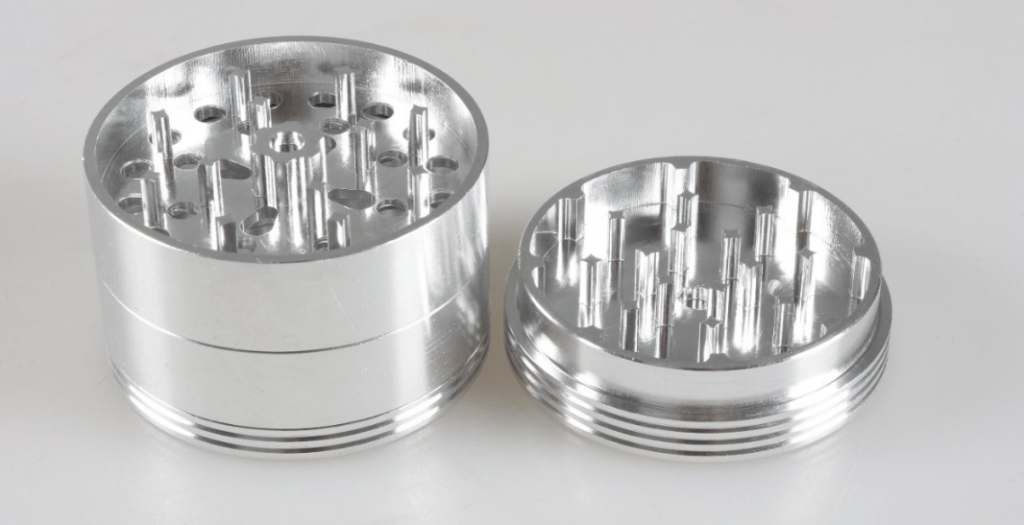

Clear Anodized CNC Milling Machined Aluminum Part

- Material: AL 7075

- Size: 80*35*23 mm

- Process: CNC Milling

- Surface treatment: Clear anodized

What Are the Advantages of Using Clear Anodized CNC Machined Aluminum Parts?

- Strength and durability: Aluminum itself is a lightweight yet strong metal, and CNC machining allows for creating parts with good dimensional accuracy and structural integrity. The clear anodized layer offers some additional protection against scratches and wear.

- Corrosion resistance: Clear anodizing enhances the natural corrosion resistance of aluminum, making the parts suitable for various environments.

- Lightweight: Aluminum is a lightweight metal, and the clear anodized layer adds minimal weight, making these parts ideal for applications where weight reduction is important.

- Aesthetics: The clear anodized layer offers a clean and attractive appearance, sometimes with a slightly reflective finish. This can be beneficial for parts that are visible in the final product.

- Electrical conductivity: While the anodizing process creates an oxide layer, clear anodized aluminum remains a relatively good conductor of electricity compared to other anodized finishes that use dyes or thicker oxide layers. This can be a benefit for some applications.

What Are Some Things to Consider When Choosing a Clear Anodized CNC Machined Aluminum Part?

- The complexity of the design: CNC machining can create intricate shapes, but very complex designs might increase production costs.

- The required strength and weight limitations: Consider the mechanical loads the part will experience and choose an aluminum alloy with appropriate strength.

- The tolerance requirements: CNC machining offers high precision, but tighter tolerances may come at an increased cost.

- The desired surface finish: While clear anodizing provides a good finish, other anodizing colors or coatings might be available depending on the application.

Why Choose JTR?

Chongqing Jin Te Rui Machine Co., Ltd. specializes in professional mass manufacturing and rapid prototyping services, such as CNC machining, die casting, 3D printing, rapid tooling and injection molding, plastic and aluminum extrusion, sheet metal prototyping, new product design and development integration. We can quickly realize your design thanks to our excellent manufacturing solutions, which can take only hours. This allows you to thoroughly test the product and make any necessary changes to improve the design before it goes into full production.