Mold making plays a crucial role in modern manufacturing, enabling the mass production of intricate parts across industries such as automotive, aerospace, medical devices, and consumer electronics. But can mold-making accurately reproduce complex geometries with fine details, undercuts, and thin walls?

The answer is yes, but achieving high-precision molds for complex shapes requires advanced technologies, specialized materials, and expert craftsmanship. In this article, we’ll explore the challenges, solutions, and best practices for handling complex geometries in mold making and introduce Chongqing Jin Te Rui Machine Co., Ltd., a trusted leader in high-precision mold manufacturing.

What Makes a Mold Making and Design Complex?

A mold is considered complex when it contains

| Feature Type | Challenges in Mold Making |

| Undercuts & Deep Cavities | Require side actions, sliders, or EDM machining to prevent defects. |

| Thin Walls | Risk of warping, uneven cooling, or injection defects. |

| Fine Surface Details | Require high-precision machining & polishing. |

| Multi-material Components | Need dual-shot injection or over molding techniques. |

| Internal Channels | Complex cooling or gas venting is required to avoid bubbles. |

| Overhangs & Tight Tolerances | Demand high-precision machining & accurate mold alignment. |

Complex geometries increase design and production challenges, requiring specialized molding techniques.

How Modern Complex Mold Making Overcomes Complexity?

To produce high-precision molds with intricate details, manufacturers use advanced techniques, including:

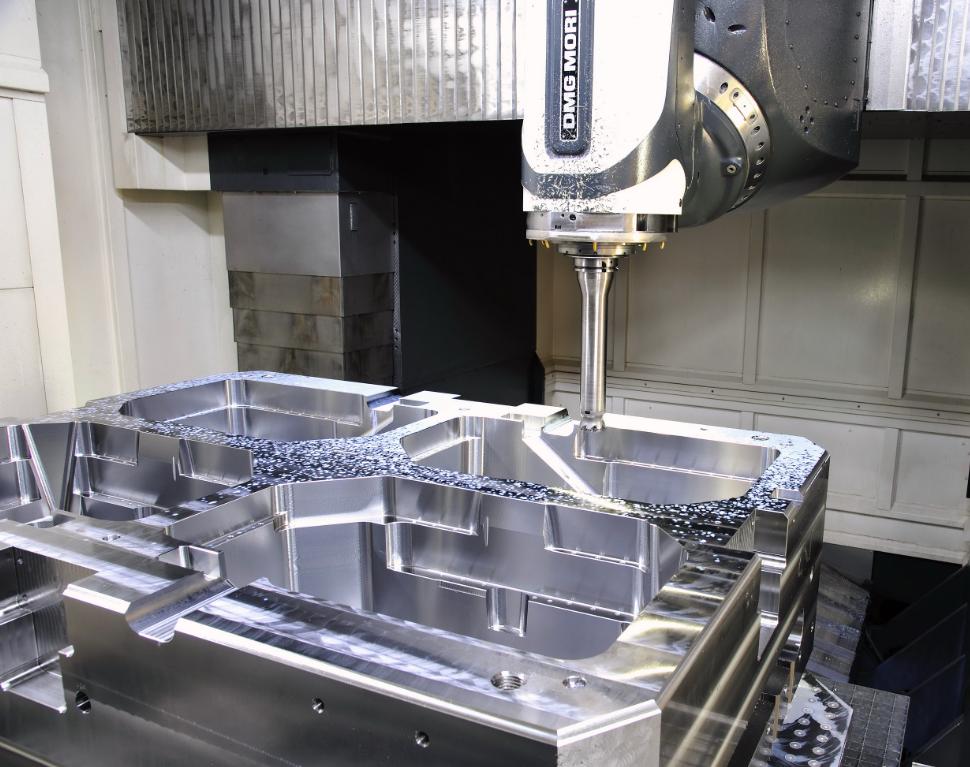

High-Precision CNC Machining

- 5-axis CNC machines can create intricate features with extreme accuracy.

- Ideal for tight tolerances and detailed surface textures.

Electrical Discharge Machining (EDM)

- Used for deep cavities, sharp corners, and undercuts.

- Provides high-precision surface finishing for intricate designs.

Advanced Injection Molding Techniques

- Gas-assisted molding reduces defects in hollow & lightweight parts.

- Overmolding allows the combining of multiple materials or colors in one part.

3D Printing for Rapid Prototyping

- 3D-printed molds help validate designs before full-scale production.

- Reduces development time for complex geometry verification.

Optimized Cooling System Design

- Conformal cooling channels prevent warping and thermal stress.

- Essential for thin-walled & intricate plastic parts.

Lead Time Considerations for Complex Molds Making

| Mold Type | Lead Time |

| Simple Injection Mold | 4 – 6 weeks |

| Multi-Cavity Mold | 6 – 10 weeks |

| High-Precision Automotive Mold | 10 – 16+ weeks |

| Die Casting Mold (Aluminum/Zinc) | 6 – 12 weeks |

The more detailed and intricate the mold, the longer the manufacturing and testing time.

Can Mold Making Handle Complex Designs?

✔ Yes! With advanced CNC machining, EDM, optimized cooling, and cutting-edge injection molding techniques, mold-making can successfully reproduce intricate geometries with extreme precision.

Why Choose Chongqing Jin Te Rui Machine Co., Ltd. for Complex Mold Making?

- Advanced Manufacturing Capabilities – Specializing in high-precision CNC machining, die casting, injection molding, and rapid prototyping.

- Expertise in Complex Geometries – Experienced in handling undercuts, fine details, thin walls, and multi-material designs.

- Fast Turnaround & High Efficiency – Utilizing 3D printing, EDM, and 5-axis CNC for reduced lead times.

- Tailored Mold Solutions – Offering custom mold design, prototyping, and mass production for diverse industries.

Product design and development in both 2D and 3D formats

JTR Machine’s product design services are mainly aimed at optimization. While we can also deal with all technical aspects of creating prototypes and parts. After 10 years of engagement in the industry, we’ve added new technologies in the whole process of product design and production, meeting the requirements of our customers and reducing the cost.

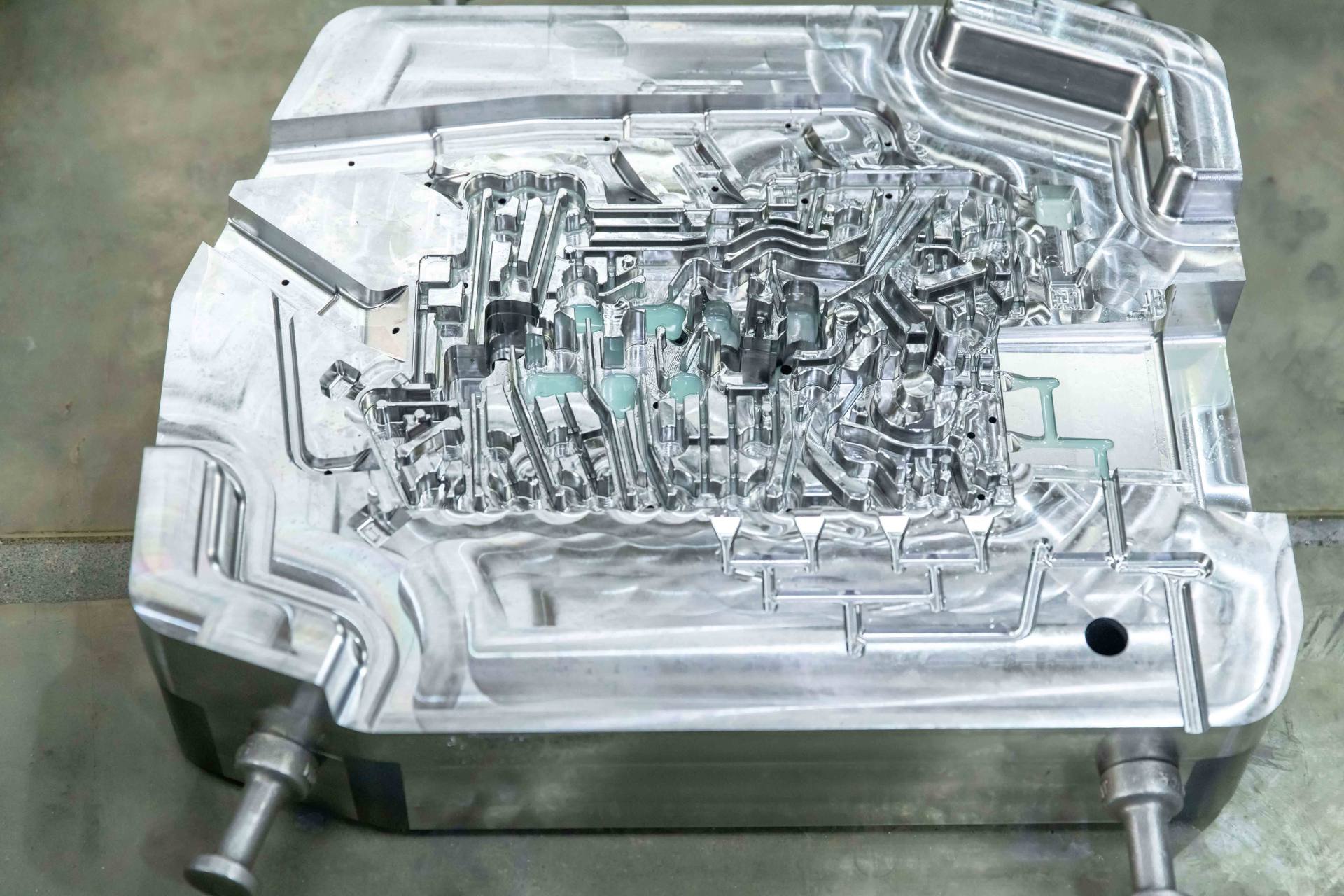

Mold making/Prototyping/Tooling

As a high-quality mold manufacturer in western China, JTR Machine’s mold-making partners can quickly make die-casting molds, injection molds, gravity casting molds, etc. Whether you need a prototype mold for short-term production or a mold for millions of batches, we can provide them with high quality and in a short lead time.