Agriculture has always been the backbone of human civilization, evolving from manual labor to mechanized operations to meet the demands of a growing global population. Agricultural machinery plays a critical role in modern farming, enabling efficiency, precision, and productivity. However, the unseen heroes behind the seamless operation of these machines are the small, precisely machined parts. From gears to fasteners, these components ensure machinery reliability and performance. Here we delves into the significance of small parts in agricultural machinery, exploring their manufacturing process and technological advancements.

The Growing Demand for Agricultural Machinery

In today’s society, agriculture faces many challenges, such as labor shortages and large-scale land management. In order to meet these challenges, the demand for agricultural machinery has shown a trend of continuous growth. Whether it is a large farm or a small farmer, they all hope to use agricultural machinery to improve production efficiency, reduce labor intensity, and improve the quality and output of agricultural products, so the machinery involved must adapt to deliver both precision and durability.

Modern farming relies on diverse machinery, including tractors, harvesters, planters, and irrigation systems. Each of these machines depends on robust and precise components to operate efficiently. The increasing population, coupled with shrinking arable land, necessitates higher productivity from each acre, emphasizing the importance of advanced machinery.

The push toward sustainable farming also adds complexity to machinery requirements, such as fuel-efficient engines and eco-friendly operations. In this context, the precision and quality of small parts ensure that the machinery can handle the rigorous demands of the field while reducing operational downtimes.

The growing demand for agricultural machinery is an inevitable result of the development of modern agriculture, which also provides a broad market space for the agricultural machinery parts processing industry. Only by producing high-quality agricultural machinery parts can the growing demand for agricultural machinery be met, thereby promoting agriculture towards modernization.

How Small Parts Make a Big Difference

The processing accuracy, materials, and processing methods of agricultural machinery parts are directly related to the performance of agricultural machinery. Errors or failures of small parts will directly affect the use of agricultural machinery and thus affect the entire agriculture.

Precision Machining

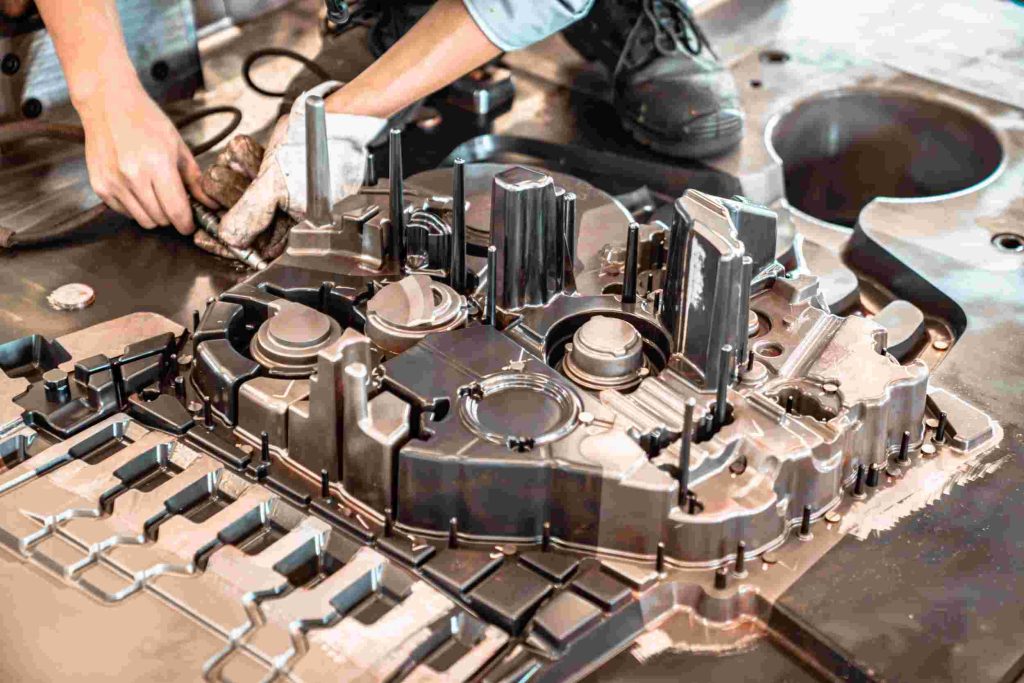

In the construction of agricultural machinery, precision machining of small parts is the key to ensuring the performance of agricultural machinery. Even a tiny part, if the machining accuracy is not enough, may affect the operation effect of the entire agricultural machinery.

For example, in the manufacture of agricultural machinery engines, the machining accuracy of the crankshaft is extremely high. If there are deviations in the crankshaft’s crank radius, the cylindricality of the journal and other parameters, it will cause the engine’s vibration to intensify and the power output to be unstable, which will affect the normal operation of the agricultural machinery. Precision machining can control the various parameters of the crankshaft within a very small error range, so that the engine can run smoothly and efficiently, and provide a reliable power source for agricultural machinery.

Precision machining is an important link in the production of small parts of agricultural machinery. It can improve the dimensional accuracy and shape accuracy of the parts, ensure the normal operation of the parts in the agricultural machinery, and thus improve the overall performance of the agricultural machinery.

Material Selection

Suitable materials are the basis for agricultural machinery parts to work for a long time in harsh agricultural environments. Different agricultural machinery parts need to choose different materials according to their working environment and functional requirements.

For example, in irrigation equipment, parts that are in direct contact with water need to have good corrosion resistance to prevent rust and damage. Therefore, these parts usually use corrosion-resistant materials such as stainless steel. For some parts that bear high loads, such as the transmission gears of agricultural machinery, high-strength alloy steel is required to ensure that they will not be deformed or damaged during the power transmission process.

Correct material selection can improve the service life and reliability of agricultural machinery parts, enable them to adapt to various complex agricultural environments, and is an important guarantee for small parts to achieve big agriculture.

Processing Technology

Advanced processing technology can process the selected materials into agricultural machinery parts that meet the requirements. The quality of the processing technology directly affects the quality and performance of the parts.

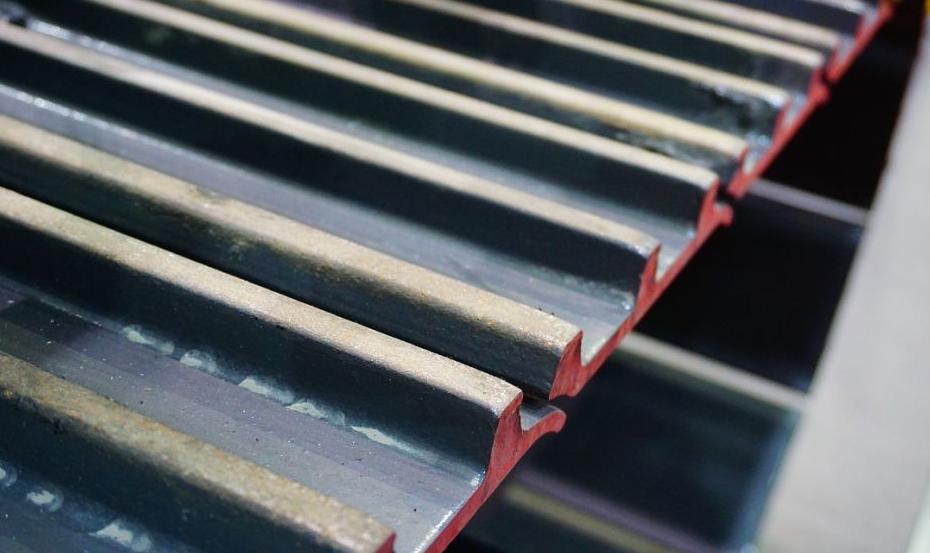

For example, when manufacturing agricultural machinery knives, the use of hot forging technology can improve the hardness and toughness of the knives. First, the steel is heated to a suitable temperature for forging, and then quenching, tempering and other heat treatment processes are performed, which can keep the knives sharp and not easy to break. The application of this processing technology enables the knives to work efficiently and stably in operations such as agricultural harvesting.

Processing technology is the key to converting materials into qualified agricultural machinery parts. By continuously optimizing the processing technology, the quality and performance of agricultural machinery parts can be improved, providing better support for agricultural production.

Innovations in Agricultural Machinery Parts Machining

With the rapid development of science and technology, traditional agricultural machinery parts processing methods face many challenges, such as low efficiency and insufficient precision. At the same time, agricultural production needs are becoming increasingly diversified and refined, which puts higher requirements on the reliability and intelligence of agricultural machinery. Agricultural machinery parts processing is also constantly innovating.

CNC Machining and Automation

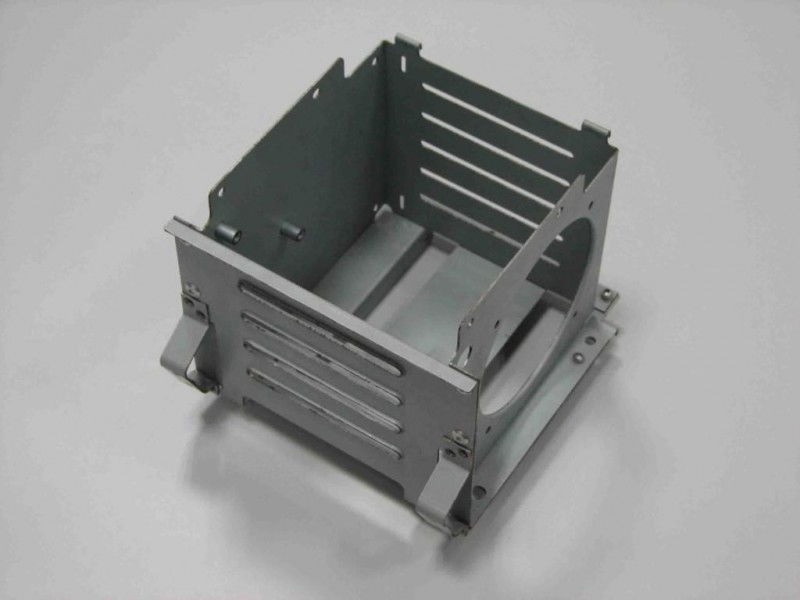

With the development of science and technology, CNC machining and automation technology have been widely used in the processing of agricultural machinery parts. These technologies can improve processing efficiency, reduce production costs, and improve the processing accuracy of parts.

In CNC machining, by writing precise programs, the machine tool can be controlled to accurately process the parts. For example, when processing agricultural machinery parts with complex shapes, CNC milling machines can accurately mill various surfaces and contours according to the program. At the same time, automation technology can realize automatic loading and unloading, automatic tool change and other operations during the processing of parts, greatly improving production efficiency.

The application of CNC machining and automation technology is an important innovation in the processing of agricultural machinery parts, which has promoted the processing of agricultural machinery parts to develop in the direction of high efficiency and high precision.

Intelligence

Intelligence is the development trend of today’s manufacturing industry, and agricultural machinery parts processing is no exception. Intelligent technology can realize real-time monitoring and optimization of the processing process.

For example, during the processing process, by installing sensors, parameters such as tool wear and part processing accuracy can be monitored in real time. When it is detected that the tool wear exceeds a certain limit, the system can automatically replace the tool; when the processing accuracy of the parts deviates, the system can adjust the processing parameters in time to ensure the quality of the parts.

Intelligent technology has brought higher quality control and production efficiency to the processing of agricultural machinery parts, and is an important direction for the innovation of agricultural machinery parts processing.

Standardization and Generalization

Standardization and generalization are of great significance in the processing of agricultural machinery parts. Standardized parts processing can ensure the quality consistency of parts, and generalization facilitates the interchange and maintenance of parts.

In agricultural machinery production, if all manufacturers process parts according to unified standards, then when repairing agricultural machinery, it is convenient to use general parts for replacement. For example, in the replacement of agricultural machinery filters, if the size and interface standards of the filters are unified, then users can easily purchase suitable filters for replacement without worrying about compatibility issues.

Standardization and generalization help to improve the versatility and interchangeability of agricultural machinery parts, reduce the maintenance cost and downtime of agricultural machinery, and have a positive impact on the smooth progress of agricultural production.

Representative Parts

Among the parts of agricultural machinery, there are some representative parts whose processing quality has a key impact on the overall performance of agricultural machinery.

Key examples include:

- Gears and shafts: Responsible for power transmission in tractors and harvesters.

- Seals and bearings: Protect moving parts from wear and environmental damage.

- Cutting blades and discs: Found in plows and harvesters, requiring sharpness and durability.

- Hydraulic components: Enable precise movement in machinery like loaders and planters.

These representative parts demonstrate how small, machined components are indispensable for large-scale agricultural machinery operations.

Although agricultural machinery parts are small, they play a vital role in the development of large-scale agriculture. From meeting the growing demand for agricultural machinery, to improving performance through precision machining, material selection and processing technology, to machining innovation and the key impact of representative parts, every link highlights the importance of agricultural machinery parts processing. With the continuous advancement of science and technology, agricultural machinery parts processing will continue to innovate and develop, providing a more solid foundation for achieving agricultural modernization, improving agricultural production efficiency and ensuring food security.

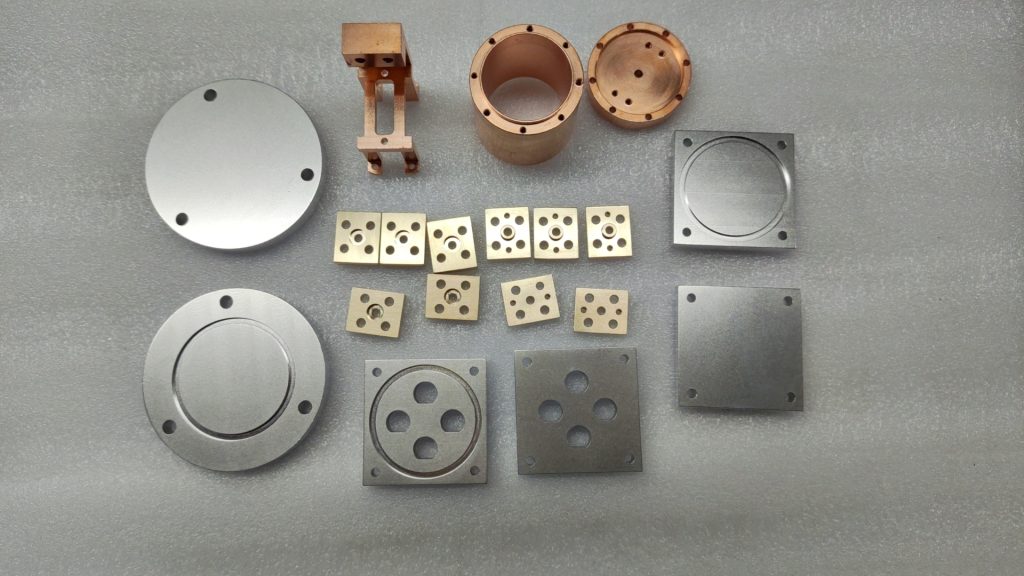

Choose JTR As Your Agricultural Machinery Parts Manufacturer

As one of China’s leading CNC parts manufacturers, JTR offers custom precision CNC machining services tailored for the agriculture industry worldwide. We provide a wide range of material options, including stainless steel, steel, alloy, brass, and bronze, to meet diverse agricultural requirements. Our advanced CNC machining capabilities encompass various methods, each with unique characteristics to ensure optimal precision and functionality. These machined parts are designed for versatile agricultural applications, from enhancing machinery performance to meeting specialized farming needs. Backed by high-quality materials, cutting-edge technology, and a dedicated professional team, JTR ensures seamless production and exceptional service for our global clients. Feel free to contact us for your needs.