Aluminum is a popular material for CNC machining due to its favorable physical properties. It is strong, making it ideal for mechanical parts, and its oxidized outer layer resists corrosion from the environment. These benefits have made aluminum parts popular in a wide range of industries, particularly automotive, aerospace, healthcare, and consumer electronics. Aluminum also has unique properties that make CNC machining easier and more efficient. Unlike many other metals with similar material properties, aluminum has excellent machinability: many of its grades can be effectively penetrated by cutting tools, chip easily, and are relatively easy to shape. This article discusses some of the key advantages of aluminum CNC machining, including why it is one of our most popular prototyping and production processes, as well as machining alternatives to aluminum. Other metals and plastics can offer similar benefits to aluminum, as well as their own distinct advantages.

What Are the Advantages of Aluminum CNC Machining?

Advantage 1: Machinability

Aluminum is a soft metal in comparison to other materials commonly used in CNC machining, such as steel and titanium. This leads to easier cutting and chip formation. Cutting tools wear less, resulting in lower production costs and downtime for tool changes. Additionally, machining aluminum uses less energy, making the process more efficient. Because of its softness, aluminum deforms less when machining. This minimal deformation enables tighter tolerances and greater precision in the finished machined parts. This is especially important for applications with precise dimensions and intricate features.

Advantage 2: Corrosion Resistance

Unlike iron (which rusts), aluminum readily reacts with oxygen, forming a thin, invisible layer of aluminum oxide on its surface. This layer acts as a passive barrier, reducing further oxidation and protecting the underlying aluminum from corrosion. Corrosion weakens and eventually destroys a material. The presence of the aluminum oxide layer mitigates this by slowing the deterioration process. This ensures that machined aluminum parts maintain their structural integrity and functionality for an extended time.

Advantage 3: Strength-to-Weight Ratio

Aluminum is a very lightweight metal. Aluminum has a density that is roughly one-third that of steel, a commonly used metal in machining. This inherent lightness translates into lighter finished parts. While pure aluminum has a moderate tensile strength, most CNC machines use aluminum alloys. These alloys are formed by combining aluminum with other elements, significantly increasing its strength properties. For example, alloy 6061, which is widely used in CNC machining, has an excellent strength-to-weight ratio while remaining machinable.

Advantage 4: Electrical Conductivity

Aluminum is an excellent conductor of electricity, making it an ideal material for the manufacture of a variety of electrical components. Aluminum, unlike other commonly machined materials such as steel, allows for an efficient flow of electricity within the finished part. This is critical for applications such as heatsinks, bus bars, and electrical enclosures.

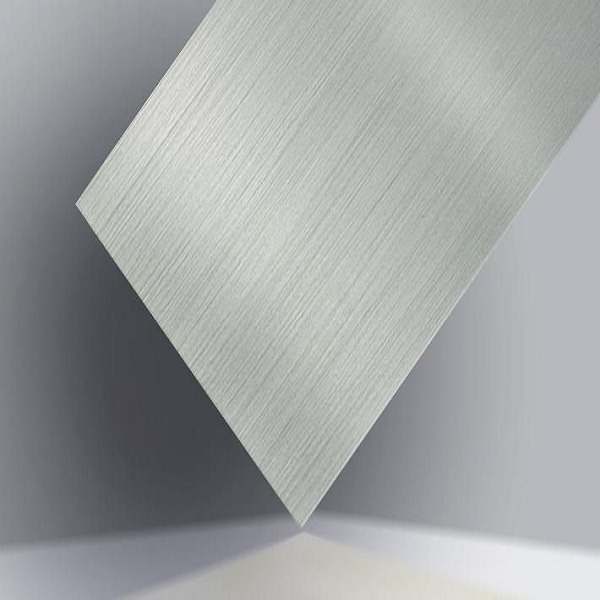

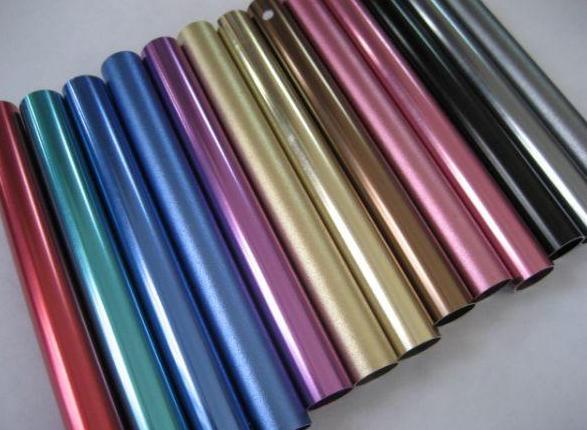

Advantage 5: Anodization Potential

Aluminum is a metal that can easily be anodized. This makes it an especially appealing option for CNC machining projects where the end product could benefit from anodization’s benefits. CNC machining allows for precise control over part design, so features can be added to optimize the subsequent anodization process.

Metals Alternatives to Aluminum in CNC Machining

Businesses may seek alternative materials to aluminum for CNC machining for a variety of reasons. After all, the metal has some drawbacks: its oxide coating can damage tooling, and it is generally more expensive than alternatives such as steel, owing in part to the high energy costs associated with aluminum production. Here are some potential machining alternatives to aluminum, emphasizing their differences and similarities to the popular silver-gray metal.

Steel & Stainless Steel

Steel and stainless steel are popular materials for CNC machining. Steels are widely used in high-stress and weld-intensive applications because of their high strength. Steel can withstand extremely high temperatures, and stainless steel can be heat-treated to increase corrosion resistance. While machining steels are intended to increase machinability, aluminum remains the more machinable of the two materials. Steel is also heavier and harder than aluminum, which may or may not be desirable in some applications. If temperature resistance is more important than weight, steel might be a better option than aluminum.

Titanium

Titanium can be used as a direct replacement for aluminum due to its superior strength-to-weight ratio, which is also one of aluminum’s primary advantages. Titanium is similar in weight to aluminum but almost twice as strong. It is highly corrosion-resistant, comparable to aluminum. Titanium’s higher price reflects its advantages. The material is ideal for aircraft components and medical devices, but it can be prohibitively expensive. Machining titanium is a viable alternative to aluminum when weight is an important consideration and, more importantly, the manufacturing budget is flexible.

Magnesium

Although magnesium is not the most popular machining material, it offers many of the same benefits as aluminum alloys. Magnesium is one of the most machinable metals, allowing for quick and efficient machining. Magnesium chips, on the other hand, are extremely flammable and aggravated by water, so machinists must proceed with caution when clearing debris.

Brass

Brass is a gold-colored metal that is highly machinable and slightly more expensive than aluminum. It is commonly used on parts like valves and nozzles, as well as structural components, and its high machinability makes it ideal for high-volume orders.

Copper

Copper and aluminum have similar material properties. Copper, on the other hand, is ideal for a wide range of electrical applications due to its high electrical conductivity. While pure copper is difficult to machine, many copper alloys are as machinable as common aluminum grades.

Combining CNC Machining With Other Processes

CNC machining is excellent at producing precise shapes and features, but it may not be suitable for all aspects of a part. Combining it with other processes allows you to incorporate elements such as textures, finishes, and additional functionalities that CNC machining alone cannot provide. In some cases, combining processes can improve productivity. For example, using CNC machining for the majority of material removal and then a laser cutting process for intricate details can be faster than using CNC machining exclusively. Some materials are not suitable for CNC machining. By combining it with other processes such as casting or 3D printing, you can broaden the materials available for your project.

CNC Machining & Die Casting

Die casting is a manufacturing process that involves pressing molten metal into a mold cavity at high pressure. It is commonly used when producing large quantities of parts because the required tool steel dies are costly to produce. Aluminum, like steel, magnesium, and zinc, is a popular metal for pressure die casting, and die-cast aluminum parts have a smooth surface finish and consistent dimensions. Die-casting aluminum components and then adding additional cuts with a machining center allows for higher finishes and more complex geometries than either process alone.

CNC Machining & Forging

Many machinable aluminum alloys are also suitable for forging, which is an age-old method of shaping metal with compressive force. Aluminum 6061, for example, is well suited to hot forging with a closed die, which is a common method for producing automotive and industrial components.

CNC Machining & 3D Printing

This is a potent combination. CNC machining excels at producing high-precision features, whereas 3D printing allows for complex geometries that would be difficult or expensive to machine traditionally. Consider a lightweight, intricate housing for delicate electronics created using 3D printing and then fitted with precisely machined metal components for added strength and stability.

Conclusion

Aluminum is the most commonly used material in CNC machining, but it is not the only option. Making informed decisions requires understanding the benefits of aluminum, such as its machinability and recyclability. However, investigating alternative metals and the benefits of combining CNC machining with other processes can open up a world of possibilities for your project. Whether you need superior strength, exceptional heat resistance, or one-of-a-kind design elements, a material and process combination is waiting to make your vision a reality. So, think beyond the aluminum block embrace the vast potential of CNC machining, and contact professionals for CNC machining services in China to make your designs a reality.