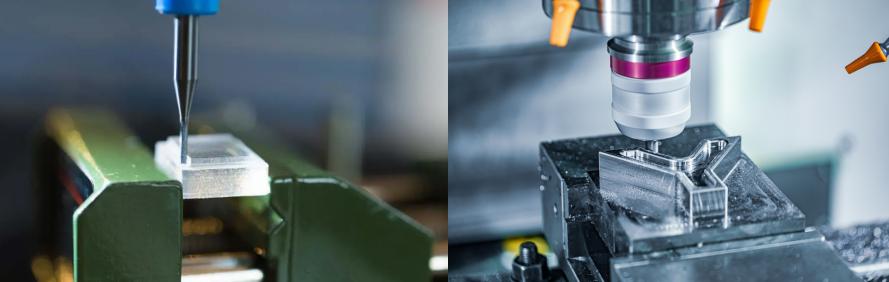

CNC milling has revolutionized the manufacturing industry, enabling the production of complex components with unprecedented precision and efficiency. While traditional CNC applications have focused on softer materials, recent advancements in technology have made it possible to effectively machine high-hardness materials. JTR looks into the intricacies of CNC milling for hard materials, exploring essential factors such as machine structure, spindle, and tool selection, cutting tool coating, and hard milling technology. By understanding these key elements, manufacturers can optimize their CNC processes to achieve exceptional results when working with challenging materials.

How to Control the Milling Effect of High-Hardness Materials in CNC milling?

Controlling the milling performance of high-hardness materials in CNC milling involves a complex interplay of factors, primarily related to machine structure, spindle and tool selection, and cutting tool coating.

Machine Structure

To achieve optimal hard milling results, a highly rigid machine with excellent vibration damping capabilities is essential. Such machines often feature granite machine beds or polymer concrete and cast iron constructions, with polymer concrete offering damping properties comparable to cast iron. Additionally, a CNC controller capable of handling both constant and rapid acceleration/deceleration dynamic demands is crucial. The rigidity of a granite machine bed makes it an ideal choice for hard milling applications.

Spindle and Tool Selection

The selection of spindles and tooling is another critical factor. High-rigidity spindles and tool holders that enhance rigidity and concentricity at the spindle interface, such as HSK series tool holders, are preferred. These choices significantly impact milling performance, as combining a high-speed spindle with the best tooling yields predictable results. Furthermore, cutting tools for hard milling applications must be coated to withstand the high heat and friction associated with these materials. While these tools may be costly, their long-term benefits often justify the initial investment.

Cutting Tool Coating and Hard Milling Technology

For high-hardness materials, hard milling technology offers a reliable and efficient approach. This technology enables shops to machine hardened steel molds, with minimal or no need for post-milling operations like polishing, saving both time and cost. With hard milling technology, mold shops can machine mold components directly on the machine, assemble them, and install them into an injection molding machine, producing a good part on the very first shot.

Benefits of CNC milling of High-Hardness Materials?

CNC milling offers several significant advantages when processing high-hardness materials:

- High Efficiency: CNC milling automates many processes, reducing manual intervention and increasing production efficiency. This results in faster cycle times and higher output.

- High Precision: CNC machines can achieve extremely high levels of precision, often down to micrometers, meeting the stringent accuracy requirements of high-hardness material milling.

- High Degree of Automation: Automation reduces the need for human intervention, lowering labor costs and minimizing the risk of human error.

- Programmability: CNC machines can be programmed to perform a wide variety of milling tasks, offering flexibility and adaptability to different part geometries and materials.

- High Reliability: The reliability of CNC milling is high, as it is less susceptible to human error, ensuring consistent part quality.

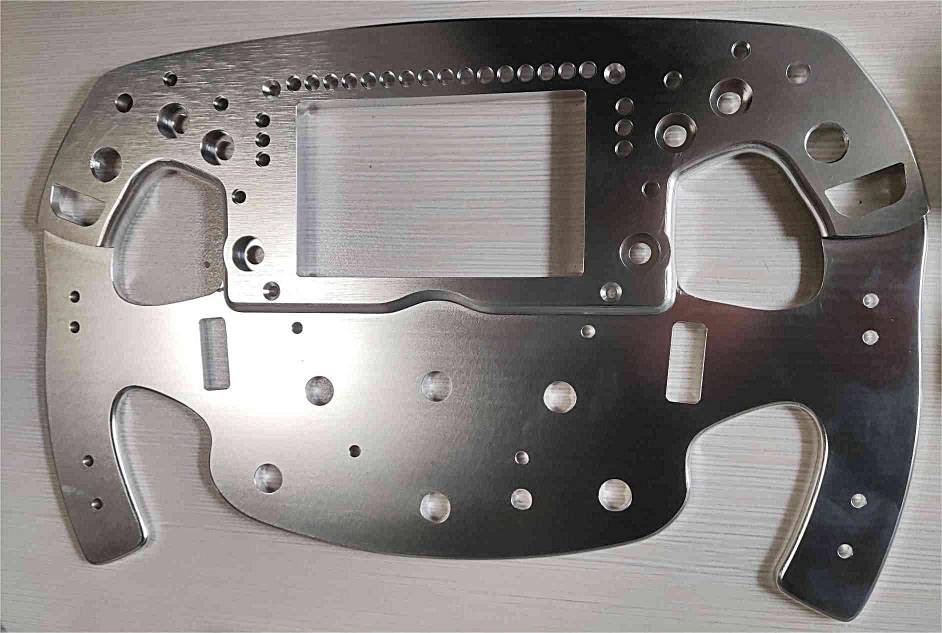

- Versatility: CNC milling centers can handle complex part geometries, making them well-suited for the milling of high-hardness materials.

- Extended Tool Life: By optimizing cutting parameters, CNC milling can reduce tool wear and extend tool life, lowering tooling costs.

- Reduced Costs: Despite the challenges of milling high-hardness materials, CNC milling can reduce overall production costs through increased efficiency and reduced scrap rates.

Specific Application Examples of CNC milling of High-Hardness Materials?

1. Aerospace Industry

In the aerospace industry, high-hardness materials such as titanium alloys and nickel-based superalloys are commonly used to manufacture aircraft engine components and structural parts. These materials demand exceptional milling precision and tool performance. For instance, Varform superhard CBN milling cutters have demonstrated excellent performance when milling high-hardness cast iron and high-hardness/wear-resistant steel.

2. Automotive Manufacturing

The automotive industry utilizes high-hardness materials like high-strength steel and stainless steel for manufacturing engine components and body structures. CNC milling is essential for processing these materials. For example, W6Mo5Cr4V2 high-speed steel plate has shown extended tool life and improved milling efficiency in the milling of automotive components.

3. Medical Device Manufacturing

In the medical device industry, high-hardness materials such as titanium alloys and aluminum alloys are used to produce surgical instruments and equipment. For example, PM60 powder metallurgy high-speed steel tools have demonstrated excellent milling performance and wear resistance in electronic component milling.

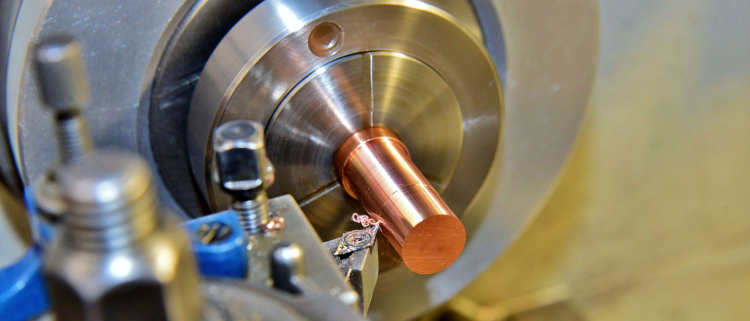

4. Electronics Manufacturing

The electronics industry relies on CNC milling to produce microstructures and precision circuit boards from materials like aluminum alloys and copper alloys. For instance, CNC milling of aluminum alloys in the electronics industry, such as the manufacturing of smartphone aluminum casings, highlights its high recyclability and environmental friendliness.

Choose CNC Milling for Your High-Hardness Materials!

CNC milling has emerged as a powerful tool for processing high-hardness materials across various industries. By carefully considering machine structure, spindle and tool selection, cutting tool coating, and hard milling technology, manufacturers can effectively control the milling process and achieve superior results. The benefits of CNC milling for hard materials, including increased efficiency, precision, and versatility, make it an indispensable asset for modern manufacturing. As one of the most famous CNC milling service suppliers in China, JTR can provide you with the most comprehensive CNC professional information and absolutely reliable CNC services. Whether you want to consult CNC milling steel parts or other matters, you can contact us directly.