The many characteristics of the die casting process make it show great advantages in improving the precision level, production efficiency, and surface quality of non-ferrous metal alloy castings. With the development of industries such as automobiles and motorcycles and the realization of design requirements such as improving the quality of die castings, saving energy consumption, and reducing pollution, the application scope of non-ferrous metal alloy die castings, especially light alloy die castings, is rapidly expanding. One of the most widely used is aluminum die casting.

Some data show that the use of aluminum alloy and magnesium alloy castings to replace steel castings in industrially developed countries is becoming an important development trend. At present, die casting has become one of the most widely used processes in the forming process of aluminum alloys for automobiles, accounting for 49% of various automobile forming processes.

However, in the production process of die-casting manufacturing, some small accidents often occur, resulting in defects in the produced parts. This article summarizes 9 defects of aluminum die castings and their solutions, I hope you can help you solve the problem when you encounter the same problem.

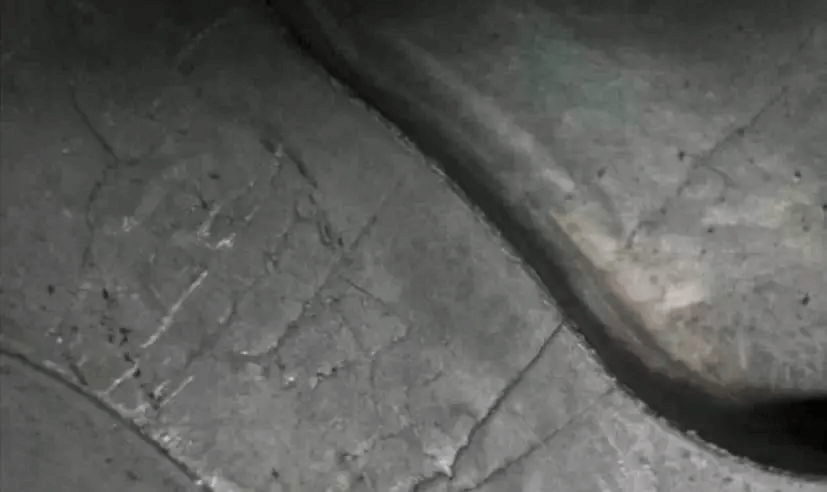

1. Flow marks and patterns appear on the surface of aluminum die casting parts

Visual inspection: There are stripes on the surface of the casting that are consistent with the flow direction of the molten metal, and there are obvious non-directional lines that are different from the color of the metal matrix, and there is no development trend.

The causes of flow marks are as follows:

1) Mold temperature is too low

2) Poor runner design and poor inner gate position

3) Material temperature is too low

4) Low filling speed and short filling time

5) The pouring system is unreasonable

6) Poor exhaust

7) Unreasonable spray

The reason for the pattern is that the paint in the cavity is sprayed too much or the paint quality is poor. The solutions and prevention methods are as follows:

1) Adjust the cross-sectional area or position of the inner runner

2) Increase the mold temperature

3) Adjust the speed and pressure of the inner runner

4) Proper selection of paint and adjustment of dosage

2. Cold insulation of aluminum die casting parts

Visual inspection: The surface of the die casting has obvious, irregular, sunken linear lines (there are two types of penetration and non-penetration), the shape is small and narrow, and sometimes the edge of the interface is smooth, which may be broken under the action of external force.

The reasons are as follows:

1) The two metal streams are butted against each other, but they are not fully fused and no inclusions exist between them, and the bonding force between the two metals is very weak

2) Pouring temperature or die-casting mold temperature is low

3) The position of the runner is incorrect or the flow path is too long

4) Low filling speed

The solutions and prevention methods are:

1) Properly increase the pouring temperature

2) Improve the injection ratio, shorten the filling time and increase the injection speed

3) Improve exhaust and filling conditions

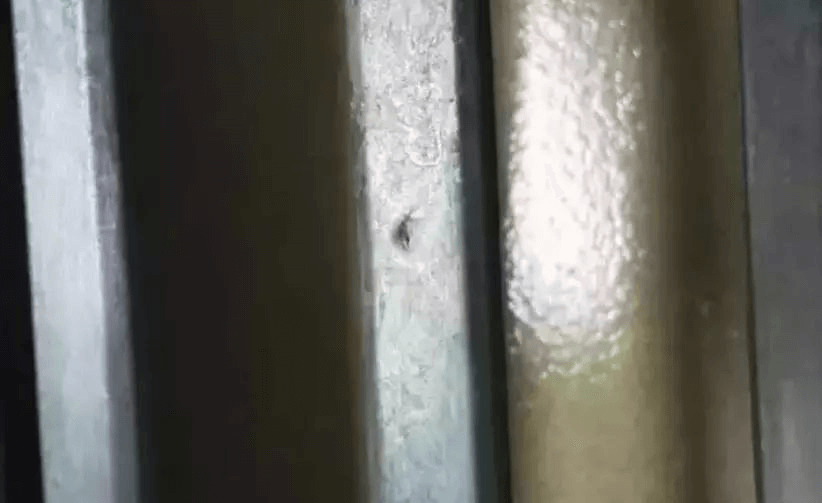

3. There are cracks on the surface of aluminum die casting parts

Visual inspection: There are net-like hairline-like protrusions or depressions on the surface of the die-casting parts, which expand and extend with the increase of the number of die-castings.

The reasons are as follows:

1) There are cracks on the surface of the die-casting cavity

2) Uneven preheating of die casting mold

The solutions and prevention methods are:

1) The die-casting mold should be annealed regularly or after a certain number of times of die-casting to eliminate the stress in the cavity

2) If there are cracks on the surface of the cavity, the molding surface should be polished to remove the crack layer.

Mold preheating should be uniform

4. Die casting aluminum parts have dents on the surface

Visual inspection: There are smooth dents (like disks) on the surface of the thickest part of the die casting.

The reasons are as follows:

1) Improper design of die castings caused by shrinkage, too large wall thickness difference, improper runner position, low injection ratio, short pressure holding time, and high local temperature of the die casting mold

2) The cooling system design is unreasonable

3) Open the mold too early

4) Pouring temperature is too high

The solutions and prevention methods are:

1) The wall thickness should be uniform

2) The thickness transition should be eased

3) Correctly select the alloy liquid introduction position and increase the cross-sectional area of the inner runner

4) Increase the injection pressure and prolong the holding time

5) Appropriately reduce the pouring temperature and die-casting mold temperature

6) Local cooling for local high temperature

7) Improve overflow conditions

5. There are traces of adhesion on the surface of aluminum die casting parts

Appearance inspection: small flakes and metal or non-metallic and metal matrix parts are welded, and the small flakes are peeled off under the action of external force.

The reasons are as follows:

1) There are metal or non-metal residues on the surface of the die-casting mold cavity

2) When pouring, the impurities are first brought in and attached to the surface of the cavity

The solutions and prevention methods are:

1) Before die casting, the cavity pressure chamber and gating system should be cleaned to remove metal or non-metal adhesions

2) The poured alloy should also be cleaned up

- Choose the right coating, the coating should be uniform

6. Surface delamination of aluminum die casting parts (skin and peeling)

Visual inspection or damage inspection: There is a clear layer of metal in the part of the casting.

The reasons are as follows:

1) The rigidity of the mold is not enough. During the molten metal filling process, the mold plate jitters

2) During the injection process, the punch crawled

3) Improper runner system design

The solutions and prevention methods are:

1) Strengthen the rigidity of the mold and tighten the mold parts to make them stable

2) Adjust the cooperation between the injection punch and the pressure chamber to eliminate the creeping phenomenon

- Reasonable design of inner runner

7. Surface friction ablation of die casting parts

Visual inspection: The surface of the die casting has a rough surface in some places.

The reasons are as follows:

1) Improper position, direction and shape of the inner runner caused by the die-casting mold (mold)

2) Insufficient cooling of the parts where the molten metal scours at the inner runner caused by the casting conditions

The solutions and prevention methods are:

1) Improve the position and direction of the inflow channel

2) Improve the cooling conditions, especially to improve the parts where the molten metal scours violently

3) Add paint to the ablated part

4) Adjust the flow rate of the alloy liquid so that it does not generate cavitation

5) Eliminate the alloy adhesion on the mold (die) tool

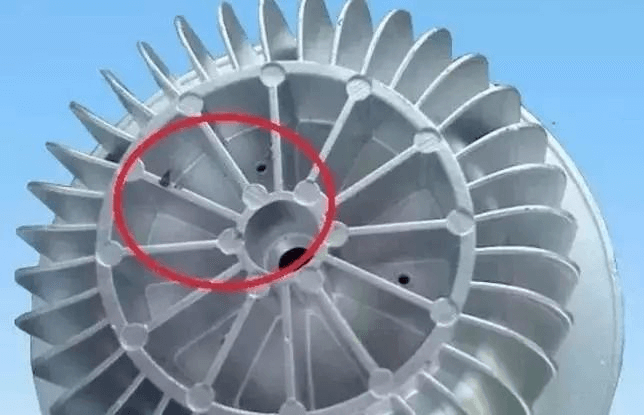

8. Erosion

Visual inspection: There are pockmarks or ridges in the local position of the die casting.

The reasons are as follows:

1) The position of the inner runner is not set properly

2) Poor cooling conditions

The solutions and prevention methods are:

1) The thickness of the inner runner should be appropriate

2) Modify the position, direction and setting method of the runner

- Strengthen the cooling of the eroded parts.

- Cracks on the surface of die casting parts

Visual inspection: The casting is placed in an alkaline solution, and the cracks are dark gray. The damage and cracking of the metal matrix are straight or wavy lines, the lines are narrow and long, and there is a development trend under the action of external force.

Causes of cracks in aluminum alloy castings:

1) The iron content in the alloy is too high or the silicon content is too low; the content of harmful impurities in the alloy is too high, which reduces the plasticity of the alloy; the aluminum-silicon alloy and the aluminum-silicon-copper alloy contain too much zinc or copper; the aluminum-magnesium alloy contains Too much magnesium

2) The mold retention time is too short, and the pressure holding time is short; the wall thickness of the casting changes drastically

3) The local wrapping force is too large, and the force is uneven during ejection

Solutions and prevention methods:

1) Correctly control the alloy composition, in some cases: pure aluminum ingots can be added to the alloy to reduce the magnesium content in the alloy; or aluminum-silicon master alloy can be added to the alloy to increase the silicon content

2) Increase the temperature of the mold (mold); change the casting structure, adjust the core pulling mechanism or make the push rod stress equal

3) Increase the draft angle and use a strong release agent locally

4) Increase the mold retention time and increase the pressure holding time