Die casting molds are at the heart of the die casting process, ensuring precise shaping of molten metals into complex components. Their quality directly influences production efficiency, product reliability, and cost-effectiveness. High-quality molds can handle rigorous production demands while delivering consistent results. In this article, we’ll explore why quality matters in die casting molds and examine five key features that define their excellence. Additionally, we’ll provide insights on how to choose a reliable mold manufacturer to meet your specific needs.

Why Quality Matters in Die Casting Molds

Quality in die casting molds goes beyond initial performance. A high-quality mold ensures:

- Precision: Accurately replicating intricate designs and maintaining tolerances.

- Durability: Withstanding the stress of high-pressure molten metal injections.

- Cost Efficiency: Reducing production downtime, defect rates, and maintenance needs.

- Longevity: Delivering a higher return on investment by lasting through numerous production cycles.

Low-quality molds often result in defects, inconsistent parts, and frequent breakdowns, leading to wasted resources and potential production delays. Prioritizing mold quality ensures smooth operations and long-term profitability.

5 Key Features of High-Quality Die Casting Molds

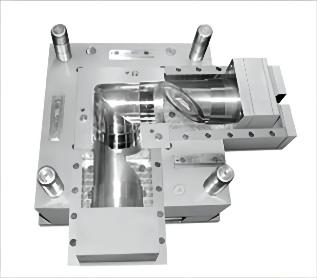

Feature 1: Precision Engineering

Precision is a cornerstone of high-quality die casting molds. It ensures the production of components with exact dimensions, meeting tight tolerances and intricate specifications.

- Tight Tolerances: High-quality molds are engineered to maintain tolerances as small as a fraction of a millimeter, crucial for applications like automotive and aerospace.

- Advanced CNC Machining: Precision molds are often crafted using CNC machines, which deliver exceptional accuracy and repeatability.

- Impact on Products: Precision engineering eliminates the risk of defects, ensuring uniformity in all manufactured parts.

Investing in precision-engineered molds guarantees consistent quality in your end products, minimizing defects and rework.

Feature 2: Durable Material Composition

The materials used in die casting molds determine their lifespan and ability to withstand demanding conditions. Some factors about materials are:

- Common Materials: High-quality molds are typically made from tool steels such as H13, known for their strength and heat resistance.

- Thermal Stability: Durable materials prevent deformation under high temperatures, maintaining mold integrity during repeated cycles.

- Treatment Processes: Techniques like nitriding or carburizing enhance surface hardness, making molds resistant to wear and corrosion.

Choosing molds made from durable materials reduces maintenance needs and ensures long-term reliability, even under challenging production environments.

Feature 3: Effective Cooling and Ventilation Systems

Efficient cooling and ventilation systems are essential for maintaining product quality and extending mold life. Here are the reasons:

- Uniform Cooling: High-quality molds have well-designed channels that ensure uniform heat dissipation, preventing defects like warping or shrinkage.

- Ventilation Importance: Proper ventilation eliminates trapped air, reducing the risk of porosity in cast parts.

- Advanced Designs: Modern molds often incorporate conformal cooling channels or optimized airflow systems for better thermal management.

Effective cooling and ventilation improve production efficiency, minimize defects, and contribute to the longevity of the mold.

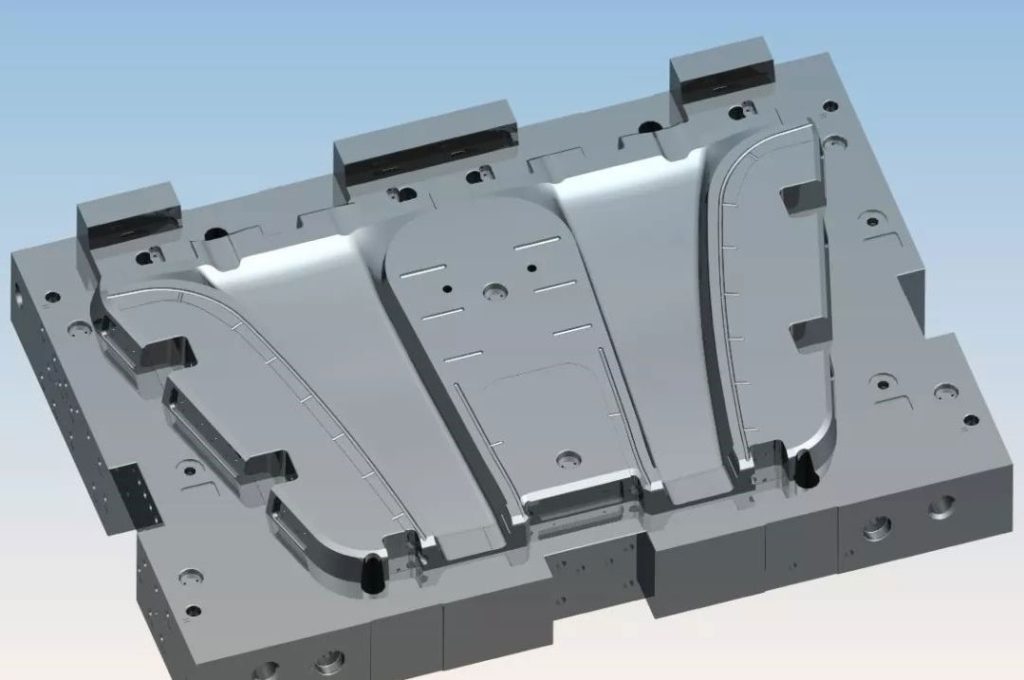

Feature 4: Customizable and Flexible Design

Flexibility and customization in mold design enable manufacturers to meet diverse production requirements and adapt to changing market demands.

- Adaptable Configurations: High-quality molds allow for modifications to accommodate different product shapes, sizes, and materials.

- Interchangeable Inserts: Some molds feature replaceable inserts, enabling quick changes without creating an entirely new mold.

- Special Features: Customization options like multi-cavity molds can significantly enhance production efficiency.

A customizable and flexible mold design ensures manufacturers can adapt to varied requirements while optimizing production workflows.

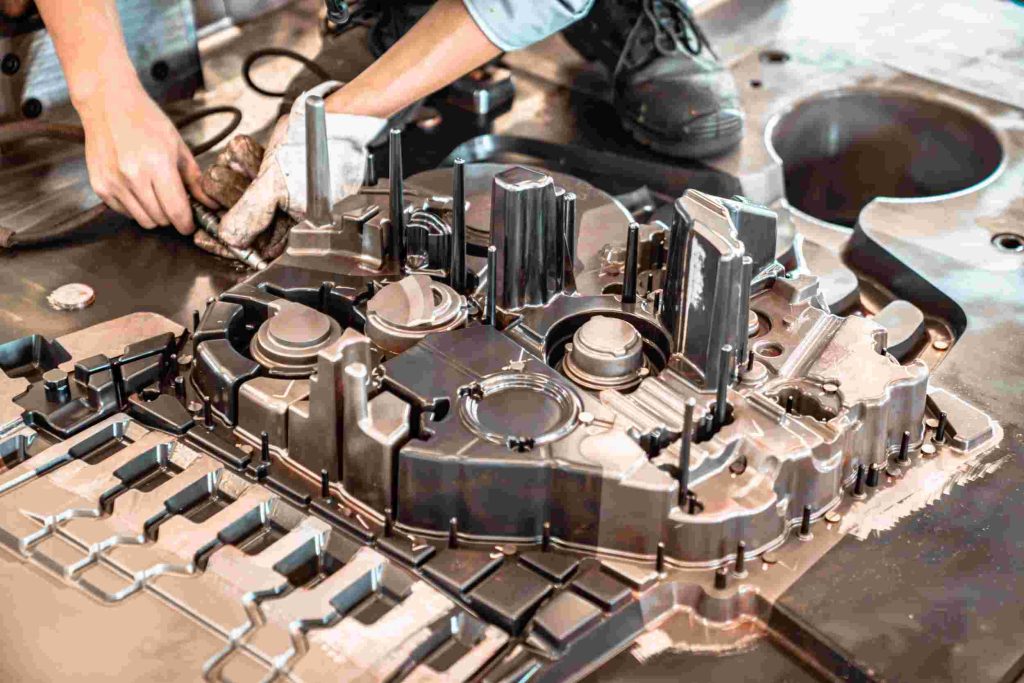

Feature 5: Resistance to Wear and Tear

Die casting molds endure high-pressure injections, intense heat, and continuous cycles, making wear resistance crucial for durability. Here are the reasons to choose wear resistance molds:

- Thermal Fatigue Resistance: High-quality molds resist cracking caused by repeated heating and cooling.

- Protective Coatings: Coatings like PVD (Physical Vapor Deposition) or nitriding enhance surface hardness and reduce friction.

- Impact on Costs: Durable molds lower maintenance expenses and reduce downtime due to repairs or replacements.

By investing in durable and well-maintained molds, manufacturers can reduce downtime, minimize production costs, and ensure consistent product quality.

High-quality die casting molds are integral to producing defect-free, durable, and precise components. By focusing on features such as precision engineering, durable materials, efficient cooling and ventilation, customizable designs, and wear resistance, manufacturers can achieve optimal results. Additionally, choosing the right mold manufacturer plays a vital role in ensuring the quality and reliability of your molds.

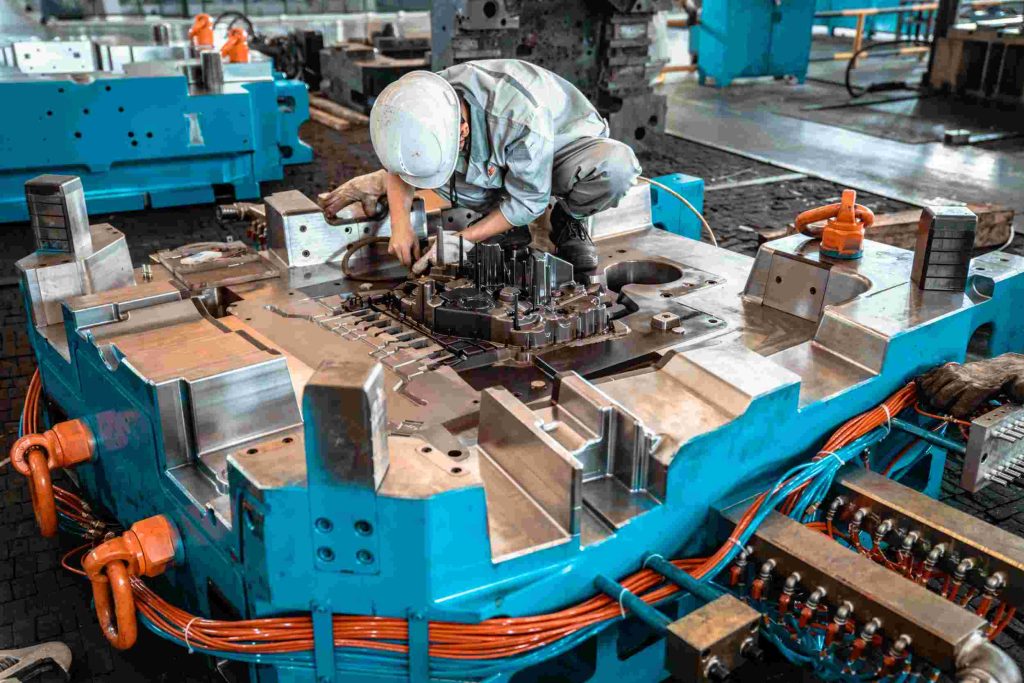

Choose a Reliable Mold Manufacturer

Selecting the right mold manufacturer is critical for ensuring quality and reliability in your production processes. JTR as a high-quality mold manufacturer, has the following strengths:

- Experience and Expertise: With 10+ years extensive experience in designing and producing die casting molds for various industry.

- Technological Capability: Utilize advanced tools like CAD/CAM software and CNC machining for precision.

- Quality Assurance: Follows strict quality control processes, including material testing and trial runs.

- After-Sales Support: Robust customer support, including maintenance and repair services.

Please feel free to partnering with us. We will try our best to ensures you receive a high-quality product tailored to your needs, supporting efficient and cost-effective production.