You’re wondering about what CNC machining means? Yes, certain industrial processes might be very unfamiliar to you, but this one actually has been applied to every “part” of our lives. It is exactly used to make parts – the parts that make up our mobile phones, garden tools, medical scalpels and even planes. It’s a kind of manufacturing process that has been so widely applied that many industries can’t live without it now. Though, many of us still remain confused about this modern manufacturing technology. So in this article, I’ve gathered 5 doubts you should clarify about CNC machining and their answers.

What is CNC Machining?

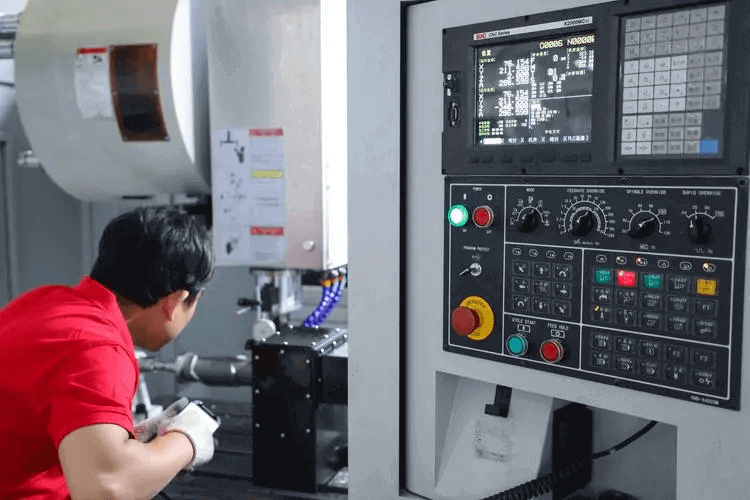

CNC machining is a manufacturing process that uses the computer to numerical control machining tools, thus produces pre-designed products. Shortly, it is the computer software instead of you operating the machining tools. Through automation, CNC machining has greatly improved the parts’ production speed and efficiency, therefore can be used for both prototyping and mass production. Another advantage of CNC machining is its ability to create high precision products. Numerical control is more precise than manual control, leading to a notable reduction in scrap rate.

The first CNC machine was created in 1957, following the creation of the APT The first CNC machine was created in 1957, following the APT language creation (Automatically Programmed Tool). In contrast, that was only an experimental device. The time when CNC machines were really dropped onto an industrial production line was in 1958. After that, parts manufacturing is completely changed. Workers can free their hands-on cutting tools and machinery, and concentrate on parts design or equipment operation. Humans are able to create parts with a higher degree of complexity (though CNC machining isn’t famous for complexity compared to other advanced manufacturing processes like 3D Printing). At present, CNC machining has become one of the most applied processes in manufacturing, producing hundreds of thousands of parts everyday.

As operating a CNC machine might appear to be easy (actually not), the working principle of the device isn’t simple at all. Next, we’re going to explore how does this process work exactly.

How dose CNC Machining work?

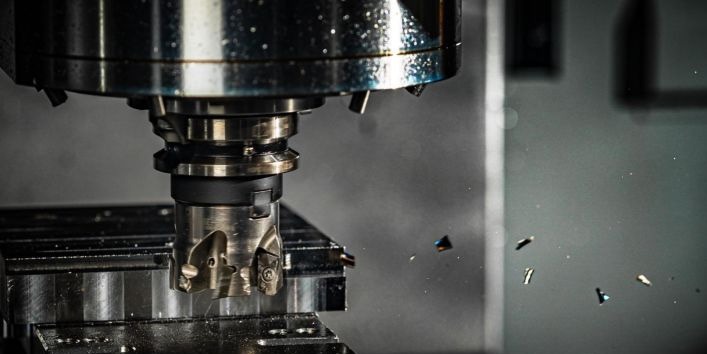

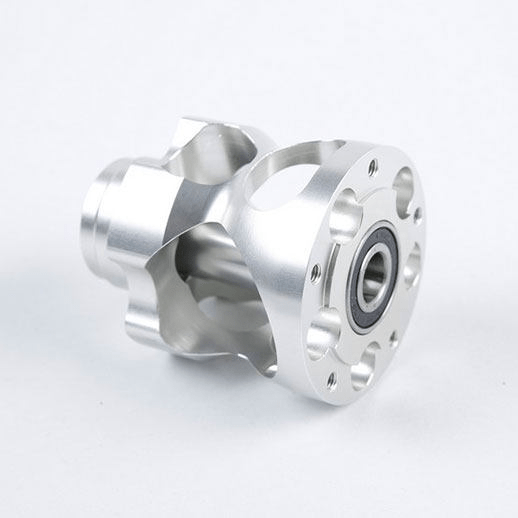

CNC Machining is one of the subtractive manufacturing processes. That is to say, it creates parts by removing layers from its original bulk. This is at the level of tool operation. A CNC machine should have three or more axes to ensure operability, accuracy, production efficiency, and part complexity. Tools or parts are moved along those axes to cut out (or other processing methods depending on the type of a CNC machine) the right shape.

If we go deeper, CNC machining is like it says – processing parts in a CNC way. CNC – Computer Numerical Control, is enabled by computer programming (using G-code or M-code), which can give instructions to the machining tools and make them move the way designed. Normally designers present their design in a CAD drawing, and a computer program converts it into machine control instructions – the parts or tools’ moving directions, the depth of cut, etc. Feedback is given by a feed back device in this whole process.

What are the types of CNC Machining?

We mentioned above that there are different types of CNC machines. So below, I have created a table showing what those types are, their main features, advantages and disadvantages.

| Types | Features | Pros. | Cons. |

| CNC Milling Machine | Large body volume/3 to 6 axis/Ability to use different cutters to carry out different functions like milling, drilling, tapping, turning, etc. | Versatility/Accuracy/Safety/Productivity | Big size/Low cost-effectiveness |

| CNC Laser Cutting Machine | Mostly 3 axis or 5axis/Mostly used to cut hard materials like metal. | Accuracy/Efficiency/Contactless cutting | Low cost-effectiveness/Metal thickness required |

| CNC Lathe | Medium body volume/3 to 6 axis/Ability to use different cutters to carry out different functions | Size/Versatility/Efficiency/Accuracy | High maintenance requirements/High operate difficulty |

| CNC Router | Medium body volume/3 to 6 axis/Route a cutting tool to process different materials fast. | Efficiency/Accuracy/Suitable for multiple materials | Low versatility |

| Plasma CNC Cutter | Medium body volume/2 axis/Use a plasma torch to cut heavy materials | Cost effective for metal cutting/Efficiency/Accuracy | Metal thickness required/Fewer dimensions/High temperatures |

| CNC Electric Discharge Machine | Medium body volume/Use electric discharge or spark to shape parts | High degree of complexity/Accuracy/Contactless/Smooth surface/Versatility | Material limitation |

What is CNC Machining most used for?

For industrial uses, CNC machining is suitable for both prototyping and mass production. As I wrote at the beginning of this article – this is a manufacturing process applied in almost every part of our lives. But still, I will list some of the most common fields or industries using CNC machining to machine parts.

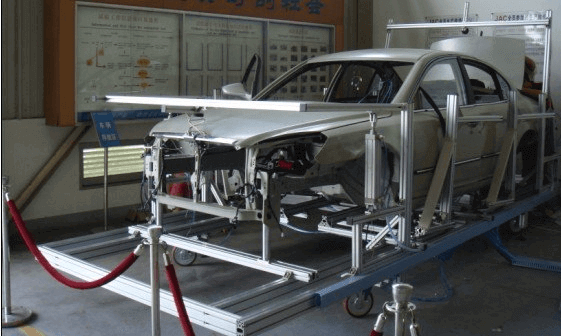

1. Automotive

Materials used in automotive industry are widely processed through CNC machining because of their compatibility. For an industry with very high requirements for parts accuracy and production efficiency, CNC machining is definitely a solution.

2. Electric products

Products like PC and mobile phones also use CNC machining to produce high-precision parts – both housing and internal components.

3. Medical

Medical appliances like scalpels require extremely high accuracy and quality. While most CNC machining processes have a very tight tolerance, meeting the requirements for medical uses.

4. Aerospace

Same as the automotive industry, aerospace industry can process its needed parts perfectly through CNC machining.

Besides those industries mentioned above, CNC machining has also been used in military, oil and gas, construction and many other fields. It may not be able to achieve the accuracy or speed of some more advanced manufacturing processes like 3D printing, or the cost-effectiveness of some old ways. But it’s surely balanced in almost all aspects, and definitely the solution for modern industries.

What Materials Can Be Used in a CNC Machine?

CNC machine tools can machining almost all materials you can think of, but the most commonly used materials are:

- Metal– such as aluminum, brass or steel.

- Plastics– such as acetal (POM), acrylic (PMMA), polycarbonate (PC) and polypropylene (PP), etc.

- Wood– usually less choice, commonly hardwood, plywood, softwood, etc.

- Foam– tend to be lighter and more durable. The two main types are carved foam and rigid foam.

But whether a certain material can be CNC machined into a certain designed shape depends on the case. JTR Machine is a highly-experienced CNC machining services provider. If you want to know whether we can meet your needs, upload your CAD file and get a free quote!