Usually, the machining of some workpieces can be very urgent, while CNC machining is a time-consuming and costly process, so how to improve the machining efficiency without affecting the machining accuracy? JTR has summarized some knowledge points for everyone.

Under the condition that the rigidity allows, the rough machining takes a larger depth of cut to reduce the number of passes and improve the productivity of the workpiece; the fine machining generally takes a smaller depth of cut to obtain a higher surface quality.

Influencing the final processing accuracy and processing efficiency of the workpiece, in addition to the reasons of the CNC machine tool itself, it should also be based on the reasonable processing route setting, the selection and correct installation of the cutting tool, the reasonable selection of the cutting amount, the programming skills, and the rapid control of dimensional accuracy. Comprehensive consideration of the aspects.

Programming Skills – a Directer Part Determines Accuracy

Numerical control programming is the most basic work of numerical control processing.

The pros and cons of the programming of workpiece processing directly affect the final processing accuracy and processing efficiency of the machine tool. It can start from several aspects such as clever use of inherent programs, reducing the cumulative error of the CNC system, and flexible use of main programs and subroutines.

- Flexible use of main procedures and subroutines

In the processing of complex molds, one mold and multiple parts are generally used for processing. If there are several parts of the same shape on the mold, the relationship between the main program and the subprogram should be used flexibly, and the subprogram should be called repeatedly in the main program until the processing is completed. It can not only ensure the consistency of processing dimensions but also improve its processing efficiency.

- Reduce the cumulative error of the CNC system

Generally, the incremental method is used to program the workpiece, and the processing is based on the previous point. In this way, the continuous execution of multiple sections of the program will inevitably produce a certain cumulative error. Therefore, try to use the absolute method for programming when programming, so that each program section is based on the workpiece. The origin is the reference so that the cumulative error of the CNC system can be reduced and the machining accuracy can be guaranteed.

Machining accuracy is mainly used for the degree of product production. Machining accuracy and machining error are both terms used to evaluate the geometric parameters of the machined surface. However, the actual parameters obtained by any machining method will not be absolutely accurate. From the perspective of the function of the part, as long as the machining error is within the tolerance range required by the part drawing, it is considered that the machining accuracy is guaranteed.

Machining accuracy refers to the actual geometric parameters (size, shape, and position) of the part after processing. The difference between them is called machining error. The size of the machining error reflects the level of machining accuracy. The greater the error, the lower the machining accuracy, and the smaller the error, the higher the machining accuracy.

The following briefly introduces the methods to improve the machining accuracy of the workpiece:

- Adjust the Process System

①Trial cutting method is adjusted by trial cutting-measuring size-adjusting the amount of cutting of the tool-cutting-retry cutting, and so on until it reaches the required size. This method has low production efficiency and is mainly used for single-piece and small-batch production.

②The adjustment method obtains the required size by adjusting the relative positions of the machine tool, fixture, workpiece, and tool in advance. This method has high productivity and is mainly used for mass production.

- Reduce MachineError

–Should improve the rotation accuracy of the bearing

①Select high-precision rolling bearings

②Using high-precision multi-oil wedge dynamic pressure bearing

③Using high-precision hydrostatic bearings

–Improve the accuracy of accessories related to the bearing

①Improve the machining accuracy of the box support hole and the spindle journal

②Improve the machining accuracy of the mating surface with the bearing

③Measure and adjust the radial runout range of corresponding parts to compensate or offset the error

–Appropriate pre-tightening of rolling bearings

①Can eliminate the gap

②Increase bearing stiffness

③Equalization of rolling element error

-Make the spindle rotation accuracy not reflected on the workpiece

- Reduce the transmission error of the transmission chain

(1) The number of transmission pieces is small, the transmission chain is short, and the transmission accuracy is high

(2) The use of reduced speed transmission is an important principle to ensure transmission accuracy, and the closer the transmission pair is to the end, the smaller the transmission ratio should be

(3) The accuracy of the end pieces should be higher than other transmission parts

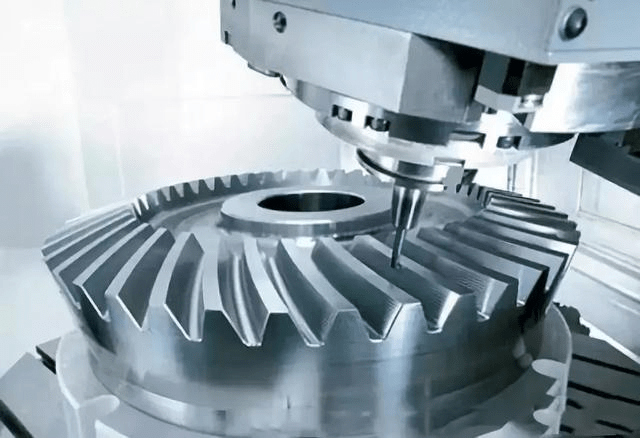

- Reduce tool wear

(1) The tool must be re-sharpened before the tool size wear reaches the sharp wear stage

(2) Use special cutting oil for sufficient lubrication

(3) The tool material should meet the process requirements

- Reduce the force deformation of the processing system

(1) Improve the rigidity of the system, especially the rigidity of weak links in the processing system

(2) Reduce the load and its changes

- Reduce the thermal deformation of the processing system

(1) Reduce the heat generation of the heat source and isolate the heat source

(2) Equilibrium temperature field

(3) Adopt reasonable machine tool component structure and assembly benchmark

(4) Accelerate the heat transfer balance

(5) Control the ambient temperature

- Reduce residual stress

(1) Increase the heat treatment process to eliminate internal stress;

(2) Reasonably arrange the technological process.

The above is the method to reduce the error of machining the workpiece, and the reasonable arrangement of the process can effectively improve the accuracy of the workpiece.

Reasonable Setting of Processing Route

The reasonable setting of the processing route and processing sequence is an important basis for optimizing the programming of workpiece processing. It can be considered from the aspects of processing trajectory and feed method.

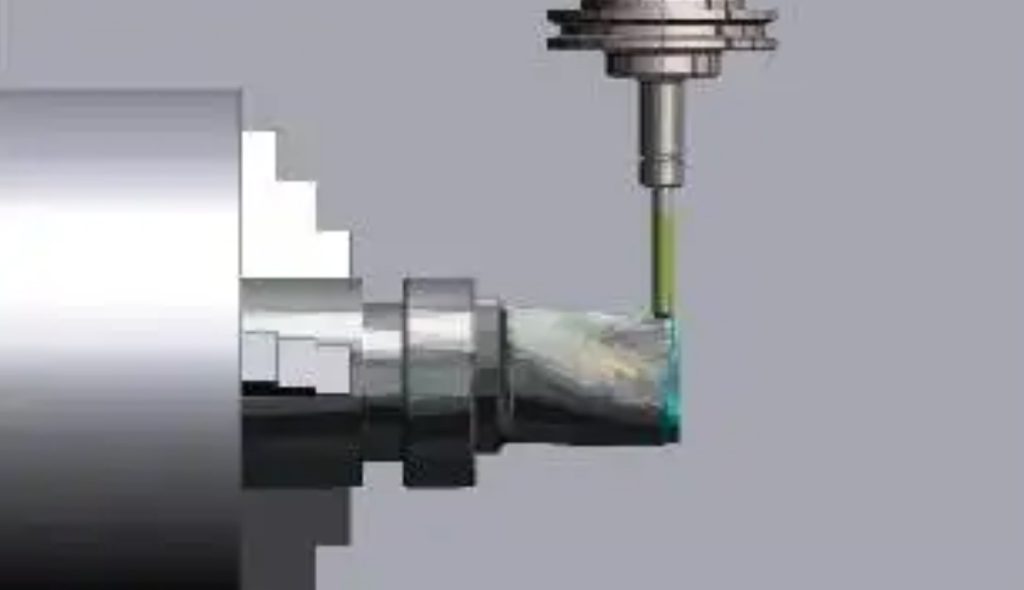

When the workpiece is CNC milled, it is necessary to select the appropriate feed method by the process requirements of the workpiece to ensure the cutting accuracy and processing efficiency of the workpiece. When milling the outer contour of a plane workpiece, the cutting-in and cutting-out route of the tool should be arranged. Try to cut in and out along the extension line of the contour curve to avoid knife marks at the junction. At the same time, down milling or up milling should be selected according to the workpiece condition in CNC milling processing.

the Selection and Correct Installation of Tools

Regardless of whether it is CNC machining or ordinary machining, the tool directly acts on the workpiece, so the machining accuracy and surface quality of the workpiece are the most important factors when it is selected and installed. Especially the workpiece is processed in the CNC machining center, and the tools are stored in the tool magazine in advance, and once the processing is started, it cannot be replaced at will. Therefore, the general principle of tool selection is convenient installation and adjustment, good rigidity, high durability, and high precision.

Reasonable Choice of Cutting Amount

The determination of the cutting amount is an important content of the CNC machining process. Its size is an important parameter of the main motion and feeds the motion of the machine tool. It has an important influence on the machining accuracy, machining efficiency, and tool wear of the workpiece. The choice of cutting amount includes cutting speed, back-cutting amount, and feed amount. The basic selection principle is: if the rigidity permits, use a larger cutting depth for roughing to reduce the number of passes and increase the productivity of the workpiece; for finishing, a smaller cutting depth is generally used to obtain a higher surface quality.