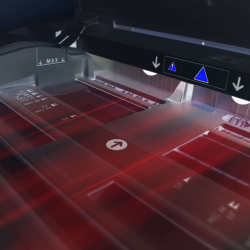

3D Printing Service

JTR offers a 3D printing service for both rapid prototyping and low-volume production. The high material versatility of metal/plastic, short lead time, and guaranteed quality has given us competitiveness in both domestic and foreign market. Get your prototypes and end-use parts at a lower cost, reduced time, and higher quality.

Our 3D Printing Services

3D Scanning

Help make your products digital with our cutting-edge 3D scanner. Able to transform your molds into a CAD drawing and make it suitable for 3D printing.

Industrial 3D Printing Design

Make a new 3D printing design for your project. If you’ve got your own design already, our engineers and designers will help you perfect it with professional advice.

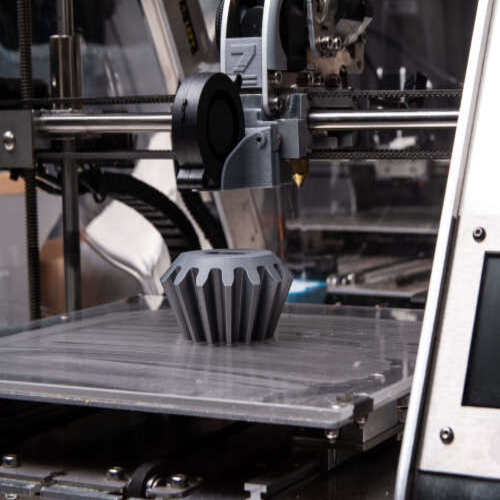

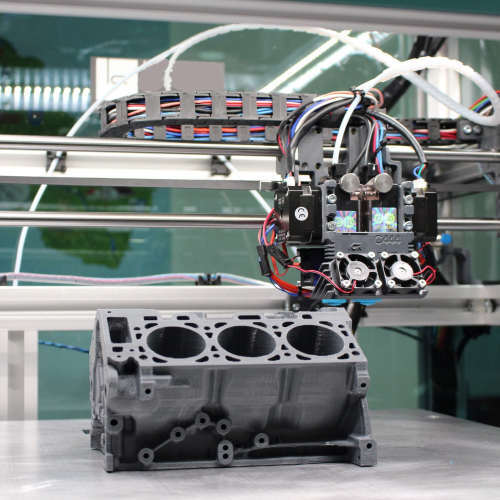

Rapid Manufacturing and Rapid Prototyping

We provide professional 3D printing services. Additive manufacturing technology uses the same processing method as CNC machining. Its advantage is that it can be manufactured quickly in small batches, and it can greatly reduce your costs.

Diversified Post-processing

We provide multiple post-processing options including mass production after prototyping, like CNC machining and metal casting. surface finishing options include anodizing, chrome & galvanized, logos & symbols, powder coat, etc. For more information, visit Surface Finishing.

Types of 3D Printing

| DMLS Printing – Metal 3D Printing Use fast-turnover metal 3D printing technology to manufacture complex-shaped functional end parts. |

| PolyJet 3D Printing A manufacturing process capable of processing multiple plastic and thermoplastic materials, producing parts with great smooth surfaces. |

| FDM 3D Printing – Fused Deposition Modeling Perfect for rapid prototyping of thermoplastic parts. Able to deliver high-precision parts within 1 day. |

| MJF 3D Printing – Multi Jet Fusion Able to produce Nylon parts for both prototyping and low volume production. FDM 3D printing material is thought to be the toughest. And our lead time is as fast as 1 business day. |

| SLS 3D Printing – Selective Laser Sintering Mostly used to process Nylon, one of the best 3D printing methods. |

| SLA 3D Printing – Stereolithography Stereolithography is a popular process chosen by designers and engineers, capable of producing the best resin parts. |

| Carbon DLS 3D Printing – Digital Light Synthesis Also called Carbon DLS, great surface details and strong material. |

3D Printing Materials Selection

| Processes | DMLS | PolyJet | FDM | MJF | SLS | SLA | DLS |

| Available Materials | Stainless Steel Hardened Steel Aluminum Titanium Copper | Elastomer (30A to 95A) | Nylon PETG PEI ASA ABS TPU PC | Nylon | Nylon Polypropylene TPU | ABS Polycarbonate Polypropylene | ABS Polypropylene |

| Max Part Size | 245 x 245 x 300 mm | 490 x 390 x 200 mm | 500 x 500 x 500 mm | 380 x 285 x 380 mm | 400 x 480 x 400 mm | 145 × 145 × 175 mm | 190 × 115 × 325 mm |

| Min Feature Size | 0.15 mm | 0.3 mm | 0.5 mm | 0.3mm | 0.3mm | 0.15mm | 0.15mm |

Stainless Steel

Aluminum

Brass

Fibers

Carbon Fibers

Plastic

3D Printing Tolerances

| Processes | Tolerances |

| DMLS | ±0.05mm |

| Polyjet | ±0.1-0.2mm |

| FDM | ±0.5mm |

| MJF | ±0.3mm |

| SLS | ±0.3mm |

| SLA | ±0.2mm |

| DLS | ±0.3mm |

Why Choose JTR for 3D Printing Service?

Material Versatility – we offer a 3D printing service for multiple materials with different processes.

High Accuracy – JTR Machine promises a thorough quality inspection before delivering the products.

Well-experienced – we’ve serviced hundreds of clients in a both domestic and foreign market

Short lead time – JTR Machine’s 3D printing service is capable of rapid prototyping within 1 business day.

Being an industry-leading 3D printing service provider, JTR Machine knows what our customers need the most. We can provide customized one-stop R&D services including 3D scanning, product design, 3D printing verification, diversified post-processing, and small batch production, along with professional 3D printing technology solutions and high-quality pre-sales and after-sales service.

We offer 3D printing solutions for different fields and industries, ensuring every one of our customers with an incredible experience of this innovative technology.

Overview of 3D Printing

What is 3D printing?

3D printing, also called additive manufacturing, is a kind of rapid prototyping technology realized by digital technology material printers. The printer reads the cross-sectional information in the file, prints these cross-sections layer by layer with liquid, powder, or sheet-like materials, and then glues the cross-sections of each layer in various ways to create an entity. This technique can create objects of almost any shape. Traditional manufacturing technologies such as injection molding can produce polymer products in large quantities at a lower cost, while 3D printing technology can produce a relatively small number of products in a faster, more flexible, and lower-cost way to meet the needs of designers for making models.

Advantages of 3D Printing

Fast Production Speed

Shortest Lead Time

Precision

High Quality Guaranteed

Degree of Complexity

Able to Process Parts with Internal Structure

Versatility

Multiple Materials Available

Applications of 3D Printing

The 3D printing technology has applications in different fields including jewelry, footwear, industrial design, architecture, engineering and construction (AEC), automotive, aerospace, dental and medical industries, education, geographic information systems, civil engineering, guns, and many other.

How to Select 3D Printing Process?

First, you need to provide 3D printed CAD files, determine the required materials, and submit them to our production team for review so that they can be optimized and produced to meet the design requirements.

Our online 3D printing service contains six 3D printing technologies that can produce plastic, metal, and elastomer parts. With dozens of advanced 3D printers, we have an unparalleled ability to deliver parts reliably within a few days. In addition to a wide selection of materials, we also offer a variety of post-processing options to improve finishes or enhance mechanical properties.

If you need help to find a 3D printing process that suits you, you can contact our experts.