In CNC machining processes, it can be divided into several parts, which should be strictly flexibly controlled based on the structure and manufacturability of the parts, the number of parts CNC machining content, the functions of the CNC machining center machine tools, the number of installations, and the production organization of the unit. And it is also advised to take the principle of process concentration or the principle of process dispersion, which must be based on the actual condition, while must strive to be reasonable. The divided processes should be in perfect condition to be carried out according to the following methods:

Tool Centralized Sorting Method

In the CNC machining process, there are many types of methods of machining parts. Tool centralized sorting method divides the process according to the tool used, using the same tool to process all the parts that can be completed on the part. In order to reduce tool change time, idle time, compression, and reduce unnecessary positioning errors, parts can be processed according to the tool method concentration, that is, in one clamping, use one tool to process all parts as much as possible, and then change another knife to process the other parts. This can reduce the number of tool changes during plastic processing, reduce idle time, reduce unnecessary positioning errors.

Process the Parts in Order

The structure and shape of each part are different, and the technical requirements of each surface are also different. Therefore, the positioning methods are different during processing, so the process can be divided according to the different positioning methods.

Each part has a different structure and shape, and each surface has a different technical requirement. So the positioning methods in the processing process are different, so the process can be divided base on different positioning methods.

For processing more parts with a lot of processing content, according to its structural characteristics, such as internal shape, shape, surface, or plane, will be processed parts into a number of parts. Generally, the plane and positioning surface are processed first, and then the hole is processed; Simple geometric shapes are processed first, then complex geometric shapes are processed; Process the parts with lower accuracy first, and then process the parts with higher accuracy requirements.

Store the Roughing and Finishing in Order

According to the machining accuracy, stiffness, deformation, and other factors of parts, the process can be divided according to the principle of coarse and fine separation, that is, rough first and then fine. At this time can use different machine tools or different machine tools for processing; For parts that are easy to deform in CNC machining, they need to be corrected because they may be deformed after rough machining. Therefore, in general, all rough and finished work must be separated.

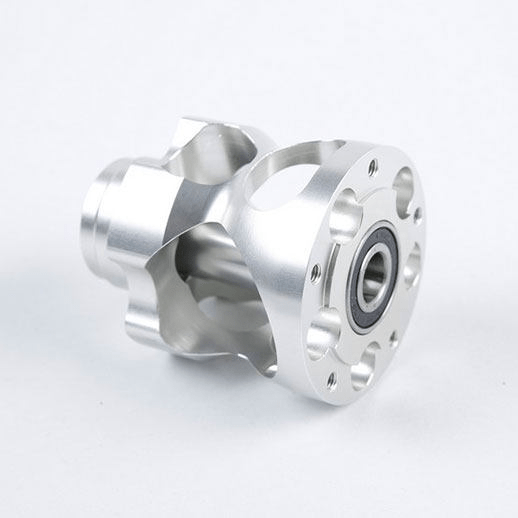

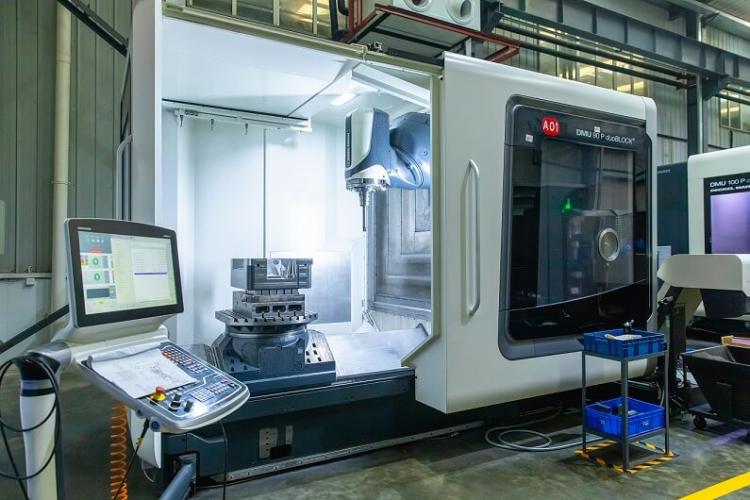

JTR is one of the most professional CNC manufacturers in China who has focused on CNC machining for decades, and the company’s core competitiveness also comes from our professional and mature technical team, high-precision equipment, and high-quality customer service. If you are looking for a high-quality CNC service, do not hesitate to contact us.