In the ever-evolving automotive industry, the demand for high-performance, lightweight materials is increasing, especially with the growing emphasis on fuel efficiency and environmental sustainability. High-precision aluminum parts machining has become a cornerstone of modern automobile manufacturing, thanks to its ability to produce complex components with tight tolerances. As the industry transitions toward electric and hybrid vehicles, the role of precision machining in producing aluminum parts is more crucial than ever. Here we will delve into three key questions: why aluminum is preferred, what high-precision machining entails, and how new energy vehicles are shaping this process, to gain a deeper understanding of high-precision aluminum parts machining for automobiles.

Why Aluminum is Preferred for Automotive Parts?

Aluminum has rapidly gained popularity in the automotive industry, replacing traditional materials like steel in several applications. But why is aluminum the material of choice for high-precision machining in automobile manufacturing? This section explores the benefits and reasons for its preference.

Lightweight and Fuel Efficiency

One of the primary reasons aluminum is favored in the automotive sector is its lightweight nature. Vehicles made with aluminum components are significantly lighter than those using steel, which leads to improved fuel efficiency and reduced emissions. In a world where environmental regulations are becoming stricter, reducing vehicle weight without compromising strength is a top priority.

Strength and Durability

Despite its lighter weight, aluminum offers excellent strength and durability, making it suitable for structural components. It can endure the stress and strain placed on automotive parts like suspension systems, engine blocks, and transmission cases.

Corrosion Resistance and Longevity

Aluminum’s natural corrosion resistance gives it a distinct advantage over steel, especially in parts exposed to the elements. This property enhances the lifespan of aluminum components, reducing maintenance costs and extending the life of the vehicle.

Recyclability and Sustainability

Another factor in aluminum’s favor is its recyclability. Aluminum can be recycled without losing its original properties, which aligns with the automotive industry’s goal of creating more sustainable and eco-friendly products.

Aluminum’s unique combination of lightweight, strength, durability, and sustainability has made it an essential material for high-precision parts in modern automobiles. Its advantages over other metals ensure its continued use, particularly in the age of electric vehicles.

What High-Precision Machining Refers to?

High-precision machining refers to the process of creating highly accurate and intricate aluminum parts using advanced manufacturing techniques. This involves precise control over factors such as dimensions, tolerances, and surface finishes.

Material Selection:

Not all aluminum is created equal. The choice of alloy directly affects the machinability, strength, and performance of the final part. Common aluminum alloys used in the automotive industry include:

- 6061 Aluminum Alloy: Known for its high strength, good corrosion resistance, and excellent weldability, making it ideal for structural components like chassis and suspension parts.

- 5052 Aluminum Alloy: Highly resistant to corrosion, especially in marine environments, this alloy is often used for fuel tanks and hydraulic systems.

- 7075 Aluminum Alloy: With an exceptionally high strength-to-weight ratio, this alloy is often used for critical components like engine blocks and transmission parts.

Selecting the right alloy ensures that the final part meets specific requirements for strength, weight, and durability.

Processing Technology

High-precision aluminum parts are typically produced using a combination of advanced machining processes, common processes include:

- CNC Milling and Turning: Computer Numerical Control (CNC) machines are the backbone of precision machining. These machines use computer programs to cut and shape aluminum parts with micrometer-level accuracy, ensuring consistency across batches.

- Multi-Axis Machining: Multi-axis CNC machines can move the cutting tool along multiple axes simultaneously, allowing for the production of complex, geometrically intricate parts that would be impossible with traditional machining methods.

These advanced techniques reduce waste and ensure that each part meets exact specifications, which is essential in mass automobile production.

Surface Treatment Methods

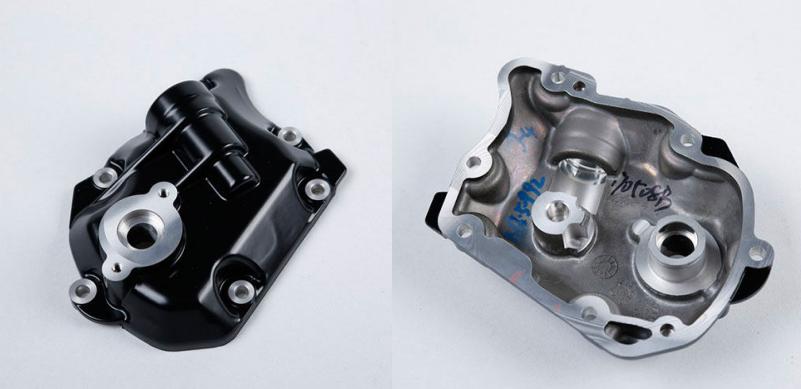

Surface treatments can enhance the material’s properties. To enhance the performance and appearance of high-precision aluminum parts, various surface treatment methods are employed:

- Anodizing: This process creates a protective oxide layer on the aluminum surface, improving corrosion resistance and providing a base for further coating or painting.

- Powder Coating: A durable, aesthetic finish that adds a layer of protection while allowing for color customization.

- Electropolishing: Used for creating a smooth, polished finish that reduces friction and enhances the appearance of parts, particularly in high-visibility areas.

High-precision machining involves careful material selection, advanced processing technologies, and proper surface treatments. These elements work together to produce reliable and efficient aluminum parts that meet the high standards of the automotive industry.

What New Technical Requirements Does New Energy Vehicle Put Forward for Precision Aluminum Parts Machining?

As the automotive industry transitions towards electric and hybrid vehicles, also known as new energy vehicles (NEVs), new demands are being placed on the machining of precision aluminum parts. These vehicles require unique components that differ from traditional gasoline-powered engines, creating new challenges for manufacturers.

Increased Need for Lightweight Parts

Electric vehicles (EVs) rely on heavy battery systems, which makes lightweight materials like aluminum even more critical. High-precision machining must accommodate the need for ultra-light components that can offset the weight of the battery without sacrificing performance.

Heat Dissipation and Electrical Conductivity

Unlike traditional vehicles, NEVs have more electrical components, from power electronics to battery casings. This creates a demand for aluminum parts with excellent electrical conductivity and thermal management. Aluminum’s superior heat dissipation capabilities make it ideal for these applications, but machining these parts requires extreme precision to ensure that they fit seamlessly into the overall vehicle system.

New Standards and Tolerances

NEVs often require tighter tolerances and new machining standards to accommodate the complexity of electric drive systems, inverters, and cooling systems. Precision machining techniques must adapt to these stringent requirements while maintaining efficiency in large-scale production.

Sustainability and Eco-Friendliness

The push toward eco-friendly vehicles also extends to the manufacturing process. NEV manufacturers demand machining processes that minimize waste, reduce energy consumption, and use sustainable materials. This has led to the adoption of green manufacturing practices in high-precision machining operations.

New energy vehicles are reshaping the requirements for precision aluminum parts machining. With their focus on lightweight, heat-dissipating, and eco-friendly components, manufacturers must adapt their processes and technologies to meet the demands of this growing market.

JTR is a precision CNC machining services provider in China, providing precision aluminium parts not only for automobile industry, but also for semiconductor, aerospace, agriculture etc.. If you are looking for a precision CNC machining manufacturer, please feel free to contact us.